×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Armada Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Brake Discs found

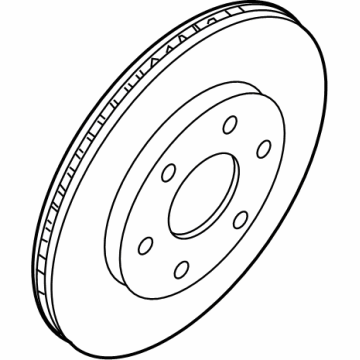

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-9FF0C$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-2 Business Days

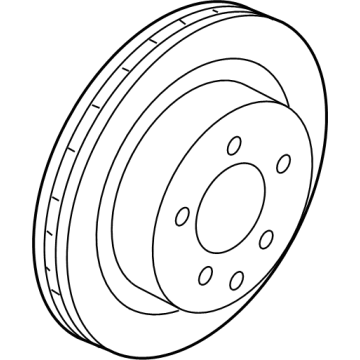

Nissan Armada Rotor Brake

Part Number: 43206-9FF0C$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-2 Business Days

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-9FF0B$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-3 Business Days

Nissan Armada Rotor Brake

Part Number: 43206-1LB0A$92.78 MSRP: $134.38You Save: $41.60 (31%)Ships in 1-3 Business Days

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-1LA2B$95.07 MSRP: $137.68You Save: $42.61 (31%)Ships in 1-3 Business Days

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-ZC01A$97.14 MSRP: $147.72You Save: $50.58 (35%)Ships in 1-2 Business Days

Nissan Armada Rotor-Disc Brake,Rear

Part Number: 43206-7S000$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-2 Business Days

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-ZR00A$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-2 Business Days

Nissan Armada Rotor Disc Brake Front

Part Number: 40206-1LA2A$95.07 MSRP: $137.68You Save: $42.61 (31%)Ships in 1-3 Business DaysNissan Armada Rotor Disc Brake Front

Part Number: 40206-ZC60A$82.86 MSRP: $120.00You Save: $37.14 (31%)Ships in 1-3 Business DaysNissan Armada Rotor Disc Brake Front

Part Number: 40206-ZC00A$97.14 MSRP: $147.72You Save: $50.58 (35%)Ships in 1 Business DayNissan Armada Rotor-Disc Brake,Rear Axle

Part Number: 43206-9FF0A$95.55 MSRP: $138.38You Save: $42.83 (31%)Ships in 1-3 Business DaysNissan Armada ROTOR-DISC BRAKE,REAR AXLE

Part Number: 43206-7JA0A$126.66 MSRP: $183.43You Save: $56.77 (31%)Ships in 1-2 Business DaysNissan Armada Disc Brake Rotor Front

Part Number: 40206-7JA0A$126.66 MSRP: $183.43You Save: $56.77 (31%)Ships in 1-2 Business Days

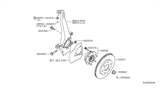

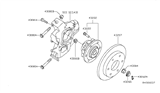

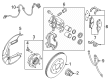

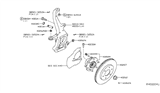

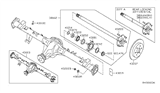

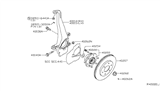

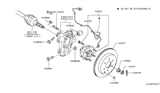

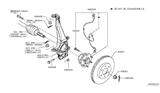

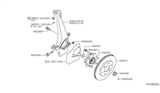

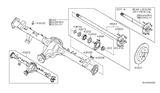

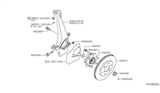

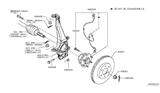

Nissan Armada Brake Disc

The Nissan Armada Brake Disc is one of the highly significant braking system spare parts that can be quickened for its reliability and performance on all models of the Nissan Armada. Turning kinetic energy into heat by friction, the Brake Disc is a safety feature and efficiency of the Nissan Armada car. Manufactured from materials such as grey iron, these discs tend to exhibit modern designs including these types of fins or vanes, thus improving the general braking force. It is relatively affordable and can be applied on both the first and second generation of the Nissan Armada, hence drivers can be assured of the stopping power of their Nissan Armada vehicle regardless of the manufacture date. It is crucial to perform prescribed care on the Brake Disc as matters such as warping or rusting are capable of decreasing the efficiency of the brake system and in extreme cases lead to hazardous situations. The towing capacity and strong engine overall are accompanied by the durability and dependability of its Brake Disc especially during times of load. Also, the drilled or slotted designs are available for better heat transfer and water elimination which contributes to the optimal braking experience. Due to this, the Nissan Armada Brake Disc is among the outstanding Nissan brakes and automotive parts in the market owing to the strong and powerful outlook, efficient technology and its focus in safety making it an important and integral part in performance and durability.

If you need any OEM Nissan Armada Brake Disc, feel free to choose them out of our huge selection of genuine Nissan Armada Brake Disc. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Armada Brake Disc Parts Questions & Experts Answers

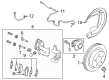

- Q: How to perform an inspect of the Brake Disc on Nissan Armada?A:Begin by loosening the wheel lug nuts, raising the vehicle, and safely supporting it on jackstands, followed by wheel removal in order to carry out brake system inspection. Check carefully for score marks, cracks or other damage on the disc surface while considering small scratches and shallow grooves as normal wear and tear. Nevertheless, more significant score marks or cracks may require disc replacement or refinishing. Disc runout is measured using a dial indicator where any measurement over 0.003 inch may cause Brake Pedal pulsation and necessitate refinishing or replacement. Ensure that the refinish thickness of the disc is above the minimum specified refinish thickness inscribed on the disc itself. When removing and installing, mark the disc's position relative to the hub before removal, next clean thoroughly both the hub flange and inside of brake disc to remove rust or corrosion before installing disc . In addition to this, when installing front calipers, also install new bolts for caliper mounting bracket and attach brake pads together with caliper later. All mounting bolts should be tightened to their recommended torque values; then after reinstalling wheels with lug nuts being tightened as per specification, lower vehicle and depress pedal so that pads contact with disk. However Brake bleeding will only be required if a brake hose or line had been disconnected from a caliper so please check brake operation carefully before returning vehicle to normal use.

Related Nissan Armada Parts

Browse by Year

2025 Brake Disc 2024 Brake Disc 2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2018 Brake Disc 2017 Brake Disc 2015 Brake Disc 2014 Brake Disc 2013 Brake Disc 2012 Brake Disc 2011 Brake Disc 2010 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc