×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

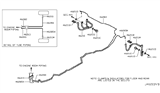

Genuine Nissan Armada Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

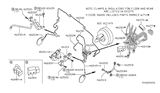

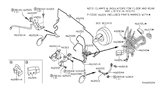

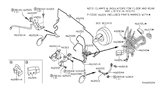

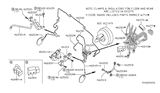

34 Brake Lines found

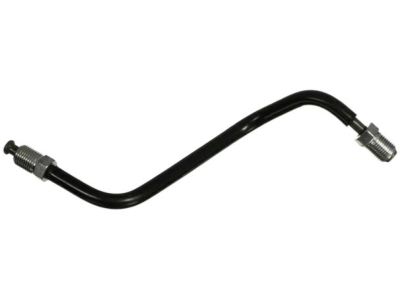

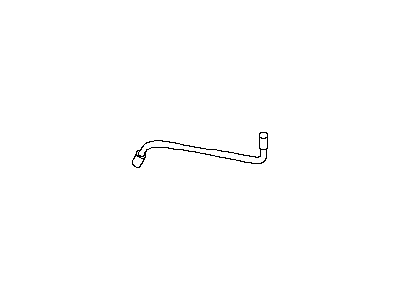

Nissan Armada Brake Tube Assembly Front Left Hand

Part Number: 46242-7S210$8.41 MSRP: $12.18You Save: $3.77 (31%)Ships in 1-2 Business Days

Nissan Armada Brake Tube Assembly Front Right Hand

Part Number: 46240-7S210$8.83 MSRP: $12.80You Save: $3.97 (32%)Ships in 1-2 Business Days

Nissan Armada Tube Assembly-Brake,Front R

Part Number: 46240-7S200$36.78 MSRP: $53.27You Save: $16.49 (31%)Ships in 1-3 Business Days

Nissan Armada Brake Hose Assembly Front

Part Number: 46211-7S002$51.11 MSRP: $74.02You Save: $22.91 (31%)Ships in 1-2 Business Days

Nissan Armada Brake Front Hose Assembly

Part Number: 46210-ZV01B$38.94 MSRP: $56.40You Save: $17.46 (31%)Ships in 1-3 Business Days

Nissan Armada Brake Hose Assembly

Part Number: 46211-ZV51A$37.03 MSRP: $53.63You Save: $16.60 (31%)Ships in 1-3 Business Days

Nissan Armada Brake Front Hose Assembly

Part Number: 46211-ZV01B$38.94 MSRP: $56.40You Save: $17.46 (31%)Ships in 1-2 Business Days

Nissan Armada Brake Hose Assembly Front

Part Number: 46210-7S002$35.06 MSRP: $50.78You Save: $15.72 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly

Part Number: 46210-ZV51A$36.15 MSRP: $52.35You Save: $16.20 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly Front

Part Number: 46211-1LA0B$60.96 MSRP: $88.28You Save: $27.32 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly

Part Number: 46210-7S010$36.15 MSRP: $52.35You Save: $16.20 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly Front

Part Number: 46210-1LA0B$60.96 MSRP: $88.28You Save: $27.32 (31%)Ships in 1-3 Business DaysNissan Armada Brake Tube Assembly Front Right Hand

Part Number: 46240-1LA2B$38.52 MSRP: $55.78You Save: $17.26 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly Front

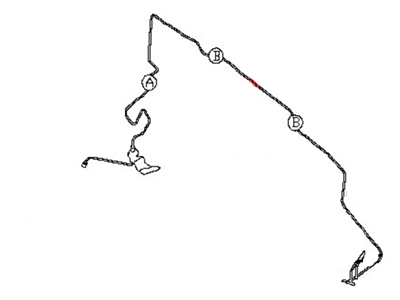

Part Number: 46210-ZR01B$38.94 MSRP: $56.40You Save: $17.46 (31%)Ships in 1-3 Business DaysNissan Armada Tube Assembly - Brake, Front LH

Part Number: 46242-1LA1A$17.13 MSRP: $24.82You Save: $7.69 (31%)Ships in 1-3 Business DaysNissan Armada Tube Assembly - Brake, Front LH

Part Number: 46242-1LA2A$38.94 MSRP: $56.40You Save: $17.46 (31%)Ships in 1-3 Business DaysNissan Armada Hose-Brake Reservoir

Part Number: 46227-EZ00A$121.91 MSRP: $172.18You Save: $50.27 (30%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly

Part Number: 46211-7S010$37.03 MSRP: $53.63You Save: $16.60 (31%)Ships in 1-3 Business DaysNissan Armada Brake Hose Assembly Front

Part Number: 46211-ZR01B$38.94 MSRP: $56.40You Save: $17.46 (31%)Ships in 1-3 Business DaysNissan Armada Rear Brake Hose Assembly

Part Number: 46211-1LA1B$41.40 MSRP: $59.97You Save: $18.57 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 34 Results

Nissan Armada Brake Line

If you need any OEM Nissan Armada Brake Line, feel free to choose them out of our huge selection of genuine Nissan Armada Brake Line. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

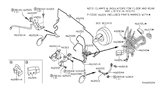

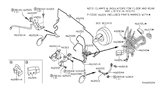

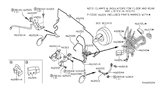

Nissan Armada Brake Line Parts Questions & Experts Answers

- Q: How to inspect and replace rubber brake hoses on Nissan Armada?A:It is recommended to check the rubber brake hoses that connect the steel brake lines to the front and rear brake assemblies approximately every six months after securely lifting the vehicle on jackstands. Check hoses for any signs of damage such as cracks, chafing, leaks, blisters, or other issues that might jeopardize their integrity. A thorough inspection should be done using a light and mirror for a complete assessment, and replace hose if any of these conditions are found. When replacing flexible brake hoses, whether they are front or rear, the process is generally the same. First loosen wheel lug nuts; then lift and secure vehicle on jackstands ; then remove wheel. Unscrew brake line fitting from hose at frame bracket that holds it (if necessary supporting frame bracket). Also remove break hose bracket from steering knuckle. Remove U-clip from female fitting at bracket, then pass hose through bracket. At caliper end of hose, remove inlet fitting bolt and take off from caliper discarding sealing washers. Connect fitting to caliper with inlet fitting bolt and new sealing washers tightened to specified torque. Route hose into frame bracket without twisting it and reconnect brake line fitting securely. Bleed caliper if necessary; install wheel and lug nuts; lower vehicle; tighten lug nuts to specified torque. For rear hoses raise rear of vehicle; support it securely on jackstands and block front wheels. Unscrew brake line fitting from hose at appropriate bracket location (s); remove U-clip to pass hose through bracket. If working on a Titan unscrew hose from caliper; if working on an Armada unscrew inlet fitting bolt and detach fitting from caliper discarding sealing washers.Titan models may have two hoses connecting the rear axle housing to the chassis, so unscrew the brake line fittings and remove the bolt securing the hose to the bracket on axle housing.Reinstallation follows reverse procedure use new sealing washers for hose fittings and bleed both rear brakes if necessary. When replacing brake lines, make sure to use the right steel brake lines and avoid copper tubing for brake system components. There are prefabricated brake lines with flared tube ends and fittings that need to be bent into the right shapes using a tubing bender. Check correct support and clearance for the new line after installation, examine master cylinder fluid level and add fluid as needed, bleed the break system, thoroughly test your breaks before getting out into traffic.

Related Nissan Armada Parts

Browse by Year

2025 Brake Line 2024 Brake Line 2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line