×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Frontier Knock Sensor

Engine Knock Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Knock Sensors found

Nissan Frontier Sensor Assembly-Knock

Part Number: 22060-30P00$219.63 MSRP: $325.20You Save: $105.57 (33%)Ships in 1-2 Business Days

Nissan Frontier Knock Sensor

Part Number: 22060-7S000$139.07 MSRP: $205.92You Save: $66.85 (33%)Ships in 1-3 Business Days

Nissan Frontier Knock Sensor

Part Number: 22060-7B000$228.58 MSRP: $338.47You Save: $109.89 (33%)Ships in 1-2 Business Days

Nissan Frontier Knock Sensor

Part Number: 22060-ZV00A$233.22 MSRP: $345.33You Save: $112.11 (33%)Ships in 1-3 Business DaysNissan Frontier Sensor Assembly Knock

Part Number: 22060-6KA0A$241.38 MSRP: $357.42You Save: $116.04 (33%)Ships in 1-3 Business DaysNissan Frontier Knock Sensor

Part Number: 22060-EZ30A$241.38 MSRP: $357.42You Save: $116.04 (33%)Ships in 1-3 Business Days

Nissan Frontier Knock Sensor

If you need any OEM Nissan Frontier Knock Sensor, feel free to choose them out of our huge selection of genuine Nissan Frontier Knock Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Frontier Knock Sensor Parts Questions & Experts Answers

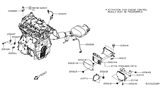

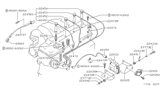

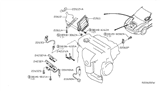

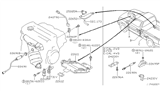

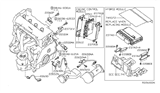

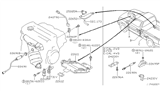

- Q: What is the purpose of the Knock Sensor and where is it located in Nissan Frontier?A:The Knock Sensor detects abnormal vibration (spark knock or pinging) in the engine. The knock control system is designed to reduce spark knock during periods of heavy detonation. This allows the engine to use maximum spark advance to improve driveability. Knock sensors produce an AC output voltage which increases with the severity of the knock. The signal is fed into the PCM and the timing is retarded to compensate for the severe detonation. On four-cylinder models, the Knock Sensor is located on the side of the engine block below the intake manifold. On V6 models, the Knock Sensor is located in the middle of the engine block underneath the intake manifold. To check, disconnect the electrical connector from the Knock Sensor. Using an ohmmeter, measure the resistance between the Knock Sensor terminal no. 2 (Pathfinder) or terminal no. 1 (Frontier/Xterra) and a good engine ground point. The resistance should be 500 to 620 K-ohms at 77-degrees F (25-degrees C). If the resistance is not as specified, replace the Knock Sensor. Note: The Knock Sensor resistance is very high, so use an ohmmeter capable of measuring at least 10 meg-ohms. To replace, on V6 models, remove the intake manifold. Disconnect the electrical connector from the Knock Sensor. Remove the sensor retaining bolt and remove the sensor from the engine block. Installation is the reverse of removal. On V6 models, install the intake manifold.

Related Nissan Frontier Parts

Browse by Year

2025 Knock Sensor 2024 Knock Sensor 2023 Knock Sensor 2022 Knock Sensor 2021 Knock Sensor 2020 Knock Sensor 2019 Knock Sensor 2018 Knock Sensor 2017 Knock Sensor 2016 Knock Sensor 2015 Knock Sensor 2014 Knock Sensor 2013 Knock Sensor 2012 Knock Sensor 2011 Knock Sensor 2010 Knock Sensor 2009 Knock Sensor 2008 Knock Sensor 2007 Knock Sensor 2006 Knock Sensor 2005 Knock Sensor 2004 Knock Sensor 2003 Knock Sensor 2002 Knock Sensor 2001 Knock Sensor 2000 Knock Sensor 1999 Knock Sensor 1998 Knock Sensor