×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Frontier Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Belt found

Nissan Frontier Timing Belt

If you need any OEM Nissan Frontier Timing Belt, feel free to choose them out of our huge selection of genuine Nissan Frontier Timing Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Frontier Timing Belt Parts Questions & Experts Answers

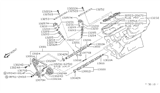

- Q: How to replace the timing belt on Nissan Frontier?A:The timing system is complex and mistakes can cause severe engine damage. Only attempt this procedure if you are highly experienced or consult an expert. Disconnect the battery cable. Raise and secure the front of the vehicle. Remove the engine under cover and drain the cooling system. Take off the engine cooling fan, fan shroud, and radiator. Loosen the water pump pulley nuts and remove the drivebelts. Remove the air conditioning compressor idler pulley and bracket, as well as any remaining idler pulleys and brackets. Detach the breather hoses and pipe from the valve covers and front of the engine. Disconnect the upper and lower radiator hoses. Disconnect hoses and wiring harness at the top of the upper timing belt cover. Remove the spark plugs and position the number one piston at TDC on the compression stroke. Remove the crankshaft pulley. Remove the outer timing belt guide from the crankshaft and the bolts securing the timing belt upper and lower covers. Confirm that the number one piston is still at TDC by aligning the timing marks on the camshaft and crankshaft sprockets. Relieve tension on the timing belt by loosening the retaining nut and rotating the tensioner. Check if the timing belt is marked and slide it off the sprockets. Inspect the camshaft and crankshaft sprockets for wear or damage. Lock the camshaft sprocket in place and remove the mounting bolt. Remove the sprocket by hand. Replace the crankshaft sprocket if necessary. Before starting the engine, rotate the crankshaft by hand to check for any resistance. Verify that you have the correct timing belt for your vehicle. Install the timing belt while aligning the marks on the belt with the punch marks on the sprockets. Remove slack from the tensioner side of the belt and retighten the nut. Turn the crankshaft clockwise two full revolutions to return the number one piston to TDC. Measure the belt deflection midway between the camshaft sprockets. Adjust the belt tension if necessary. Place a feeler gauge between the tensioner pulley and the belt and slowly turn the crankshaft until the gauge is in place. Tighten the tensioner locking nut while keeping the tensioner steady. Turn the crankshaft for two revolutions and recheck the belt tension. Install the components that were removed during disassembly.