×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

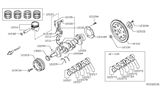

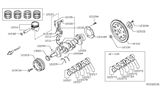

Genuine Nissan Maxima Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

42 Rod Bearings found

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-JA10C$14.92 MSRP: $21.07You Save: $6.15 (30%)Ships in 1 Business Day

Nissan Maxima Bearing Connecting Rod

Part Number: 12111-31U10$18.93 MSRP: $26.10You Save: $7.17 (28%)Ships in 1-3 Business Days

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-JA11C$14.27 MSRP: $19.67You Save: $5.40 (28%)Ships in 1-2 Business Days

Nissan Maxima Bearing - Connecting Rod

Part Number: 12111-02P00$10.34 MSRP: $17.97You Save: $7.63 (43%)

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-4W000$15.28 MSRP: $21.07You Save: $5.79 (28%)Ships in 1-2 Business Days

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-4W001$14.27 MSRP: $19.67You Save: $5.40 (28%)Ships in 1-3 Business Days

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-JA10A$16.29 MSRP: $22.45You Save: $6.16 (28%)Ships in 1-3 Business Days

Nissan Maxima Connecting Rod Bearing

Part Number: 12111-40V10$10.34 MSRP: $17.97You Save: $7.63 (43%)Nissan Maxima Connecting Rod Bearing

Part Number: 12111-JA11B$16.60 MSRP: $22.88You Save: $6.28 (28%)Ships in 1-3 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12111-JA10B$16.29 MSRP: $22.45You Save: $6.16 (28%)Ships in 1-3 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12117-4W000$20.00 MSRP: $27.57You Save: $7.57 (28%)Ships in 1-3 Business DaysNissan Maxima Bearing-Connecting Rod,Std

Part Number: 12111-JA12B$16.81 MSRP: $23.17You Save: $6.36 (28%)Ships in 1-3 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12111-31U12$12.58 MSRP: $17.77You Save: $5.19 (30%)Ships in 1-2 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12111-JA12C$15.28 MSRP: $21.07You Save: $5.79 (28%)Ships in 1-2 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12117-JA10C$15.33 MSRP: $21.13You Save: $5.80 (28%)Ships in 1-3 Business DaysNissan Maxima Bearing Connecting Rod

Part Number: 12114-02P00$10.11 MSRP: $13.93You Save: $3.82 (28%)Ships in 1-3 Business DaysNissan Maxima Bearing-Connecting Rod,Us

Part Number: 12117-JA10B$15.27 MSRP: $21.57You Save: $6.30 (30%)Ships in 1-3 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12117-31U00$10.72 MSRP: $14.78Limited AvailabilityYou Save: $4.06 (28%)Nissan Maxima Connecting Rod Bearing

Part Number: 12111-JA11A$16.60 MSRP: $22.88You Save: $6.28 (28%)Ships in 1-3 Business DaysNissan Maxima Connecting Rod Bearing

Part Number: 12111-31U02$12.58 MSRP: $17.77You Save: $5.19 (30%)

| Page 1 of 3 |Next >

1-20 of 42 Results

Nissan Maxima Rod Bearing

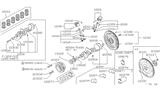

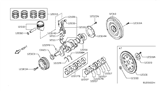

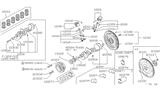

Nissan Maxima Rod Bearing is an important component that has the great impacts on the dependability and fuel salvage of the Nissan Maxima series. It stands to hold the crankshaft and the connecting rods in position in order to drive the vehicle at a proper rotation with low friction thus being an important component that enhances engine efficiency. Rod Bearings used by Nissan includes bi metal and tri metal constructions, which are used throughout the different models of Maxima. The well-loved three-metal Rod Bearing is used in performance models, as it provides increased wear resistance and the most excellent lubrication properties for high-revving engines. This makes the Maxima to perform better while also contributing to its safety because the engine is safeguarded under all manner of driving. The Maxima Rod Bearing is flexible in that it fits in multiple generations of the Maxima so that Nissan drivers can finest the functional recuperation of this part. Some other specifications that solve the customer requirements in the automotive segment include proprietary coatings and an eccentricity setting exclusive to the Rod Bearing, which enhance the clearance of oil and the frictional characteristics. Thus, the Nissan Maxima Rod Bearing can be identified as a proven example of Nissan's continued adherence to the principles of the mechanical vanguard, caliber improvement of the Maxima, and further consolidation of its position as a sports luxury sedan.

If you need any OEM Nissan Maxima Rod Bearing, feel free to choose them out of our huge selection of genuine Nissan Maxima Rod Bearing. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Rod Bearing Parts Questions & Experts Answers

- Q: What should be considered when inspecting and replacing main and connecting rod bearings during an engine overhaul on Nissan Maxima?A:As the engine's overhaul proceed, although new main and connecting rod bearings are often fitted, it is informative to retain several of the old bearings for analysis. Failure to bear causes can occur from lack of oil or lack of clean oil, dirt or foreign particle, overloading of the engine, and corrosion among others must be checked before assembling again so that they might not be repeated. Regarding bearings, they have to be taken out from their s Mining th My location and spread neatly so as to match any defects with the crankshaft journal. It concerns foreign particles that can get inside the engine during its assembly, in the course of filter usage, or due to some machineries; these foreign particles may lodge themselves in the bearing material resulting to scoring or gouging. To avoid such failures, all parts must be cleaned and the oil as well as the filter changed frequently. The causes of lubrication breakdown are high temperatures, overloading, oil leakage, or blocked oil ways leading to adhesion of bearing material and hence high temperatures. Driving habits also affect bearings; for example, low speed combined with high gear results in high load, short trips expose them to moisture and gases resulting in corrosion. Some of the issues include tight bearing pocket or improper housing layout, trapped material between the bearings or housing halves and other such conditions. If original bearings are worn or if oil clearances are incorrect, new bearings must be obtained, especially if the crankshaft has been reground, as undersize bearings depending of the amount of material taken off would have to be used. The bearings for the automotive machine shop are available in standard sizes which has standard grinder in steps of 0.010 inch, and bluing done on the reground crankshafts show the amount done. Finally, oil clearance should be confirmed with the help of the Plastigage if there are doubts and it is always wiser to consult a machine shop or the parts department in the event of a doubt concerning the choice of bearings.

Related Nissan Maxima Parts

Browse by Year

2023 Rod Bearing 2022 Rod Bearing 2021 Rod Bearing 2020 Rod Bearing 2019 Rod Bearing 2018 Rod Bearing 2017 Rod Bearing 2016 Rod Bearing 2014 Rod Bearing 2013 Rod Bearing 2012 Rod Bearing 2011 Rod Bearing 2010 Rod Bearing 2009 Rod Bearing 2008 Rod Bearing 2007 Rod Bearing 2006 Rod Bearing 2005 Rod Bearing 2004 Rod Bearing 2003 Rod Bearing 2002 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing 1985 Rod Bearing