×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

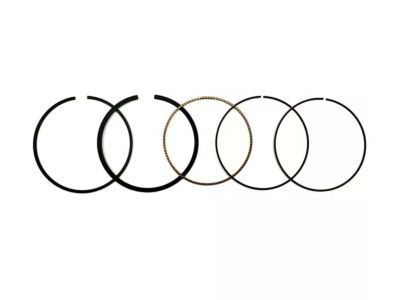

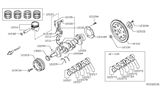

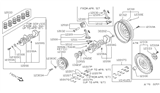

Genuine Nissan Maxima Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Piston Ring Sets found

Nissan Maxima Piston Ring Set

Part Number: 12033-8J100$310.25 MSRP: $438.20You Save: $127.95 (30%)Ships in 1-3 Business Days

Nissan Maxima Piston Ring Set

Part Number: 12033-JA10D$165.40 MSRP: $233.62You Save: $68.22 (30%)Ships in 1-3 Business Days

Nissan Maxima Piston Ring Set

Part Number: 12033-9HP0A$319.74 MSRP: $451.62You Save: $131.88 (30%)Ships in 1-3 Business DaysNissan Maxima Piston Ring Set

Part Number: 12033-96E01$158.26 MSRP: $239.78You Save: $81.52 (34%)Ships in 1-2 Business DaysNissan Maxima Ring Set Piston

Part Number: 12035-JA10D$176.06 MSRP: $242.50You Save: $66.44 (28%)Ships in 1-2 Business DaysNissan Maxima Ring Set Std

Part Number: 12033-21V00$128.37 MSRP: $181.32Limited AvailabilityYou Save: $52.95 (30%)Nissan Maxima Ring Set Std

Part Number: 12033-21P00$128.37 MSRP: $181.32Limited AvailabilityYou Save: $52.95 (30%)Nissan Maxima Ring Set Piston

Part Number: 12033-38U01$176.49 MSRP: $249.28Limited AvailabilityYou Save: $72.79 (30%)Nissan Maxima Piston Ring Set

Part Number: 12033-38U00$176.49 MSRP: $249.28Limited AvailabilityYou Save: $72.79 (30%)

| Page 1 of 2 |Next >

1-20 of 30 Results

Nissan Maxima Piston Ring Set

If you need any OEM Nissan Maxima Piston Ring Set, feel free to choose them out of our huge selection of genuine Nissan Maxima Piston Ring Set. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

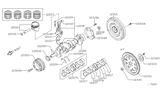

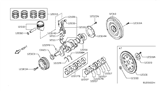

Nissan Maxima Piston Ring Set Parts Questions & Experts Answers

- Q: How should the end gaps of piston rings be checked and corrected before installation on Nissan Maxima?A:Before fitting the new Piston rings be sure to measure the ring end gaps-the piston ring side clearance should have been checked. Stagger the piston/connecting rod assemblies and the new ring sets to be comparable to the piston and cylinder during the end gap measurement and engine buildup process. Place the top ring into the first cylinder aligning its extremities with the cylinder walls by the help of the piston, putting it as close as possible to the bottom of the cylinder. To obtain the end gap dimension, place feeler gauges between the two adjacent ring ends until the desired value is reached; it should barely move with the gauge inserted. The next three stages are, if gap is incorrect, check that rings are correct; if rings are incorrect, perform incorrect ring check; and if incorrect gap is greater than rings, perform two rings clockwise turn. If this space is narrow then the rings are filed and in regard to type of the ring set and material procedures of exchanging the rings may be required. Further end gap is not much of an issue as long as it is not more than 0.040-inch; align measurements with maximum standards. When filing is required, apply the vise, and oil the jaws; file slowly and remember to check the available space after every filing. The same is done for every ring in all the cylinders and with due care that the rings, pistons, and cylinders must be matched. When the end gaps of the piston are adjusted, fit the rings upon the pistons beginning the oil control ring, this is comprised three parts. Place the spacer/expander into the grove in the right side of the cylinder head and make sure that if the anti-rotation tang is in the right place; the next step is to fit the lower and upper side rails, do not use the piston ring installation tool for this operation since it may damage the rails. Before installing the oil ring components, ensure that sides rails fit in the grove and will turn smoothly around it. The next ring should be inserted into the groove of the mixer shaft with the identification mark facing up; the rest of the process is specific to the manufacturer's guidelines. Then place the top ring in the same position, with the said mark upwards and do the same thing for all the pistons and rings.

Related Nissan Maxima Parts

Browse by Year

2023 Piston Ring Set 2022 Piston Ring Set 2021 Piston Ring Set 2020 Piston Ring Set 2019 Piston Ring Set 2018 Piston Ring Set 2017 Piston Ring Set 2016 Piston Ring Set 2014 Piston Ring Set 2013 Piston Ring Set 2012 Piston Ring Set 2011 Piston Ring Set 2010 Piston Ring Set 2009 Piston Ring Set 2008 Piston Ring Set 2007 Piston Ring Set 2006 Piston Ring Set 2005 Piston Ring Set 2004 Piston Ring Set 2003 Piston Ring Set 2002 Piston Ring Set 2001 Piston Ring Set 2000 Piston Ring Set 1999 Piston Ring Set 1998 Piston Ring Set 1997 Piston Ring Set 1996 Piston Ring Set 1995 Piston Ring Set 1994 Piston Ring Set 1993 Piston Ring Set 1992 Piston Ring Set 1991 Piston Ring Set 1990 Piston Ring Set 1989 Piston Ring Set 1988 Piston Ring Set 1987 Piston Ring Set 1986 Piston Ring Set 1985 Piston Ring Set