×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

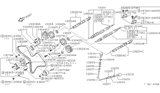

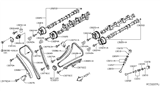

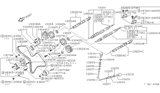

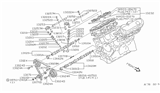

Genuine Nissan Maxima Valve Stem Oil Seal

Engine Valve Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Valve Stem Oil Seals found

Nissan Maxima Seal-Oil,Valve

Part Number: 13207-84A00$6.92 MSRP: $9.53You Save: $2.61 (28%)Ships in 1-2 Business Days

Nissan Maxima Seal-Lip Valve

Part Number: 13207-3Z00A$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Maxima Seal-Oil,Valve

Part Number: 13207-3Z000$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Maxima Seal-Oil Valve

Part Number: 13207-81W00$7.42 MSRP: $10.23You Save: $2.81 (28%)Ships in 1-2 Business Days

Nissan Maxima Seal-Oil,Valve

Part Number: 13207-D4201$6.75 MSRP: $9.53You Save: $2.78 (30%)Ships in 1-2 Business Days

Nissan Maxima Seal-Oil Valve

Part Number: 13207-21002$7.42 MSRP: $10.23You Save: $2.81 (28%)Ships in 1-3 Business Days

Nissan Maxima Valve Stem Oil Seal

If you need any OEM Nissan Maxima Valve Stem Oil Seal, feel free to choose them out of our huge selection of genuine Nissan Maxima Valve Stem Oil Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Valve Stem Oil Seal Parts Questions & Experts Answers

- Q: How can broken valve springs and defective valve stem seals be replaced without removing the cylinder heads on Nissan Maxima with SOHC engine?A:Essentially worn out valve springs and faulty valve stem seal can be repaired without removing the cylinder heads,usually this involves the usage of two tools and a compressed air. Initiation requires the preliminary step of the removal of the valve cover or several covers and the Rocker Arm along with the lifters' guide assembly. OPOP the spark plug out of the affected cylinder, if the entire set of valve stem seals is to be replaced, then pop out all the spark plugs. Let the crankshaft come to a position where the piston of the affected cylinder is on the Top Dead Centre. If changing all valve stem seals, begin with cylinder # 1 and work from that cylinder to number 2 and so on, always following the firing order. Feed a long adapter into the spark plug hole and attach the other end of the air hose to the present compressed air source. As much as the spark plug tubes are relatively long, the long spark plug adapter, which accompanies a hose attachment, is required. Press the air to the cylinder and push the shop rags in the cylinder head holes around the valves so that small parts and tools will not fall in the engine. Apply lubrication on the thread of the valve stem and then remove it using the valve spring compressor; you need to compress the spring so that you can remove the valves stem locks. The valves should seat by air pressure; if they cannot, the cylinder head may have to be removed for a valve grind. Drop the spring retainer, the shield, and the valve spring and then, pull out the valve stem seal. Twirl the rubber band or the tape over the top of the valve stem so that it will not drop to the combustion chamber then deflate it. Check and look at the valve stem for any signs of wear; it should turn with ease in the guide without getting stuck. Apply pressure on the end of pipe to keep the valve closed, then, undo the tape or rubber band. Using engine oil, grease the valve stems and replace the valve stem seals for the intake and the exhaust but do not mix them. Place the inner and outer springs over the valve with the tightly coiled spring towards the head of the cylinder, next is the valve spring retainer. Compact the valve springs and put the valve stem locks in the groove, and than apply little amount of grease for the locks to stay fixed. Pull out the spring tool and make certain the valve stem lock shoulder is in place. Remove the air hose coupling and take out the spark plug adapter from SP hole then replace the lifter assembly and the rocker arm assembly, and the valve cover. Last of all, put the spark plug(s) back and connect the wire(s), cranking the engine and looking for oil drops or any abnormal noises at the vicinity of the valve cover.

Related Nissan Maxima Parts

Browse by Year

2023 Valve Stem Oil Seal 2022 Valve Stem Oil Seal 2021 Valve Stem Oil Seal 2020 Valve Stem Oil Seal 2019 Valve Stem Oil Seal 2018 Valve Stem Oil Seal 2017 Valve Stem Oil Seal 2016 Valve Stem Oil Seal 2014 Valve Stem Oil Seal 2013 Valve Stem Oil Seal 2012 Valve Stem Oil Seal 2011 Valve Stem Oil Seal 2010 Valve Stem Oil Seal 2009 Valve Stem Oil Seal 2008 Valve Stem Oil Seal 2007 Valve Stem Oil Seal 2006 Valve Stem Oil Seal 2005 Valve Stem Oil Seal 2004 Valve Stem Oil Seal 2003 Valve Stem Oil Seal 2002 Valve Stem Oil Seal 2001 Valve Stem Oil Seal 2000 Valve Stem Oil Seal 1999 Valve Stem Oil Seal 1998 Valve Stem Oil Seal 1997 Valve Stem Oil Seal 1996 Valve Stem Oil Seal 1995 Valve Stem Oil Seal 1994 Valve Stem Oil Seal 1993 Valve Stem Oil Seal 1992 Valve Stem Oil Seal 1991 Valve Stem Oil Seal 1990 Valve Stem Oil Seal 1989 Valve Stem Oil Seal 1988 Valve Stem Oil Seal 1987 Valve Stem Oil Seal 1986 Valve Stem Oil Seal 1985 Valve Stem Oil Seal