×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

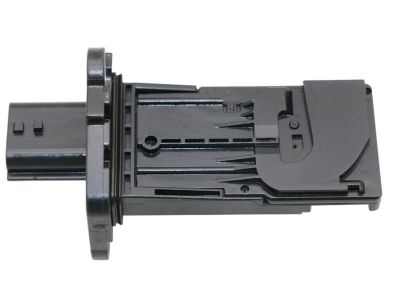

Genuine Nissan Pathfinder Mass Air Flow Sensor

MAF Sensor Meter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Mass Air Flow Sensors found

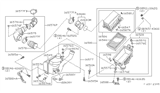

Nissan Pathfinder Air Flow Sensor

Part Number: 22680-7S000$220.69 MSRP: $326.77You Save: $106.08 (33%)Ships in 1-2 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-5RB0A$237.66 MSRP: $351.90You Save: $114.24 (33%)Ships in 1-3 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-6CA0B$210.63 MSRP: $311.88You Save: $101.25 (33%)Ships in 1-3 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-1MG0A$230.71 MSRP: $341.62You Save: $110.91 (33%)Ships in 1-3 Business Days

Nissan Pathfinder Mass Air Flow Sensor Maf Sensor

Part Number: 22680-3VA0A$233.82 MSRP: $346.22You Save: $112.40 (33%)Ships in 1-3 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-7S00A$220.69 MSRP: $326.77You Save: $106.08 (33%)Ships in 1-2 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-BV80B$237.66 MSRP: $351.90You Save: $114.24 (33%)Ships in 1-2 Business Days

Nissan Pathfinder Mass Air Flow

Part Number: 22680-CA000$263.62 MSRP: $402.35You Save: $138.73 (35%)Ships in 1-2 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-5J000$491.55 MSRP: $750.23You Save: $258.68 (35%)Ships in 1-3 Business Days

Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-4W011$216.62 MSRP: $320.75You Save: $104.13 (33%)Ships in 1-3 Business DaysNissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-88G00$939.31 MSRP: $1444.73You Save: $505.42 (35%)Ships in 1-3 Business DaysNissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-6N211$219.77 MSRP: $325.42You Save: $105.65 (33%)Nissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-4W001$512.35 MSRP: $781.98You Save: $269.63 (35%)Ships in 1-3 Business DaysNissan Pathfinder Mass Air Flow Sensor

Part Number: 22680-6N201$674.06 MSRP: $1028.78You Save: $354.72 (35%)

Nissan Pathfinder Mass Air Flow Sensor

If you need any OEM Nissan Pathfinder Mass Air Flow Sensor, feel free to choose them out of our huge selection of genuine Nissan Pathfinder Mass Air Flow Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Pathfinder Mass Air Flow Sensor Parts Questions & Experts Answers

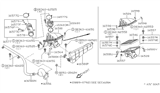

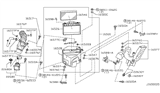

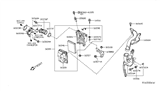

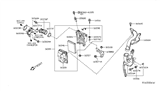

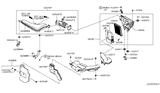

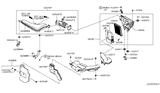

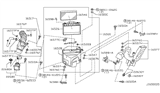

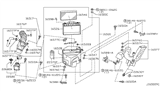

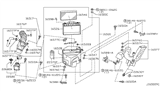

- Q: How to inspect and replace the Mass Airflow (MAF) sensor on Nissan Pathfinder?A:The Mass Airflow (MAF) sensor is located on the throttle body for four-cylinder models and in the air intake duct for V6 models, and it measures the molecular mass of incoming air by use of a hot-wire sensing element. This sensor detects air that passes over this wire, which then cools and changes into a voltage that is relayed to the Powertrain Control Module (PCM). The PCM uses this information to calculate the required fuel injector pulse width for producing a desired air/fuel ratio. Problems like surging, stalling, rough idling etc may be caused by MAF failure and it could lead to certain trouble codes being set in EEC system. Before checking MAF sensor operation, check power and ground circuits. Plug out MAF sensor electrical connector. With ignition turned ON (engine not running), connect positive voltmeter lead to B+ wire terminal of harness connector while connecting negative lead to suitable engine ground point. If not, assess EGGS relay and related circuits. Also recommended is checking the ground circuit for continuity between connector and PCM. On 3.5L V6 models, with ignition ON and using positive voltmeter lead connected to reference wire terminal and negative lead connected to suitable engine ground point should produce around 5.0 volts-if there is no reference voltage present then suspect possible wiring harness fault or need PCM diagnosis. Reconnect electrical connector to MAF sensor; backprobe MAF sensor signal wire terminal with suitable probe while connecting positive voltmeter lead to probe and negative lead to suitable engine ground point; with ignition key ON voltmeter should read less than 1.0 volt (for 2002-2003 3.5L models approximately 1 volt). When starting an engine at idle, expect a range from about 1.0 upwards of 1.8 volts, which will increase as engine rpm goes higher from 1.6 to 3.0 volts. Unfortunately, simulating driving conditions in your driveway is impossible; however, one must see the voltmeter's needle rising as the engine speed goes up and if this does not happen you need to either replace or check on other parts of the MAF sensor system such as wiring harness integrity. In case they are okay, it would be advisable to consult dealer's service department or any qualified repairer for a possible PCM diagnosis. Noteworthy is that even with normal voltage readings, some signal faults may not show up when using a voltmeter; nevertheless, a dealer service department or qualified repairer should perform a sensor test and these problems are undetectable with voltmeter yet still give rise to driveability issues. With four-cylinder models, the air filter housing has to be removed followed by unplugging the MAF sensor electrical connector then removing retaining screws that secure the MAF sensor to the throttle body allowing for replacement of sensor. Contrarily, for V6 models note that plastic MAF sensor body and air duct are an integrated assembly which cannot be taken apart as separating them will be impossible without damaging any of the components therefore never try to do this as it will destroy either part. Unplug electrical connector from MAF sensor; remove clamp securing sensor to intake air duct and extract four fasteners that hold sensor onto air filter housing so as to allow new unit installation and connection process flow smoothly.

Related Nissan Pathfinder Parts

Browse by Year

2025 Mass Air Flow Sensor 2024 Mass Air Flow Sensor 2023 Mass Air Flow Sensor 2022 Mass Air Flow Sensor 2020 Mass Air Flow Sensor 2019 Mass Air Flow Sensor 2018 Mass Air Flow Sensor 2017 Mass Air Flow Sensor 2016 Mass Air Flow Sensor 2015 Mass Air Flow Sensor 2014 Mass Air Flow Sensor 2013 Mass Air Flow Sensor 2012 Mass Air Flow Sensor 2011 Mass Air Flow Sensor 2010 Mass Air Flow Sensor 2009 Mass Air Flow Sensor 2008 Mass Air Flow Sensor 2007 Mass Air Flow Sensor 2006 Mass Air Flow Sensor 2005 Mass Air Flow Sensor 2004 Mass Air Flow Sensor 2003 Mass Air Flow Sensor 2002 Mass Air Flow Sensor 2001 Mass Air Flow Sensor 2000 Mass Air Flow Sensor 1999 Mass Air Flow Sensor 1998 Mass Air Flow Sensor 1997 Mass Air Flow Sensor 1996 Mass Air Flow Sensor 1995 Mass Air Flow Sensor 1994 Mass Air Flow Sensor 1993 Mass Air Flow Sensor 1992 Mass Air Flow Sensor 1991 Mass Air Flow Sensor 1990 Mass Air Flow Sensor 1989 Mass Air Flow Sensor 1988 Mass Air Flow Sensor 1987 Mass Air Flow Sensor