×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Sentra Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

128 Axle Shafts found

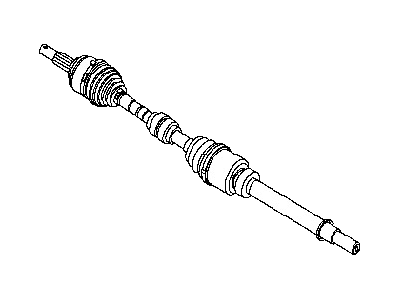

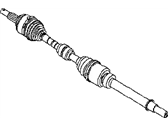

Nissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-3RC0A$370.16 MSRP: $564.95You Save: $194.79 (35%)Ships in 1-3 Business Days

Nissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-3RC0A$376.29 MSRP: $574.32You Save: $198.03 (35%)Ships in 1-3 Business Days

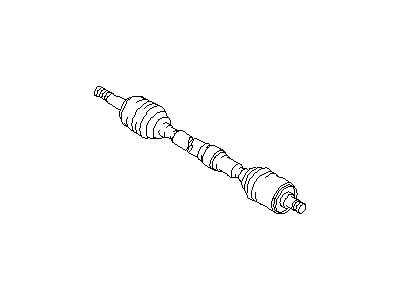

Nissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-ET000$421.72 MSRP: $580.88You Save: $159.16 (28%)Ships in 1-2 Business Days

Nissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-4AF0C$533.93 MSRP: $814.92You Save: $280.99 (35%)Ships in 1-3 Business Days

Nissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-3ZM0B$598.24 MSRP: $913.07You Save: $314.83 (35%)Ships in 1-3 Business Days

Nissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-4AF0C$640.88 MSRP: $978.15You Save: $337.27 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-6LB0A$419.78 MSRP: $640.68You Save: $220.90 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-6LB0A$383.10 MSRP: $584.72You Save: $201.62 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-3RC0B$317.56 MSRP: $484.68You Save: $167.12 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-3RC0B$318.67 MSRP: $486.38You Save: $167.71 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft

Part Number: 39100-9AA0A$390.19 MSRP: $595.53You Save: $205.34 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-3ZM0B$514.43 MSRP: $785.15You Save: $270.72 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-ET200$390.19 MSRP: $595.53You Save: $205.34 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Right Hand Shaft Assembly

Part Number: 39100-ET80C$414.92 MSRP: $571.52You Save: $156.60 (28%)Ships in 1-2 Business DaysNissan Sentra Front Drive Shaft Assembly Right Hand

Part Number: 39100-0M610$455.68 MSRP: $588.42You Save: $132.74 (23%)Ships in 1-2 Business DaysNissan Sentra Front Drive Shaft

Part Number: 39101-ET80B$414.92 MSRP: $571.52You Save: $156.60 (28%)Ships in 1-2 Business DaysNissan Sentra Front Drive Right Hand Shaft Assembly

Part Number: 39100-4AF0D$533.93 MSRP: $814.92You Save: $280.99 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft

Part Number: 39101-4AF0D$640.88 MSRP: $978.15You Save: $337.27 (35%)Ships in 1-3 Business DaysNissan Sentra Front Drive Shaft Assembly Left Hand

Part Number: 39101-60Y15$455.42 MSRP: $588.09You Save: $132.67 (23%)Ships in 1-2 Business DaysNissan Sentra Shaft-Front Drive,R

Part Number: 39202-60Y06$54.42 MSRP: $75.02Limited AvailabilityYou Save: $20.60 (28%)

| Page 1 of 7 |Next >

1-20 of 128 Results

Nissan Sentra Axle Shaft

If you need any OEM Nissan Sentra Axle Shaft, feel free to choose them out of our huge selection of genuine Nissan Sentra Axle Shaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Sentra Axle Shaft Parts Questions & Experts Answers

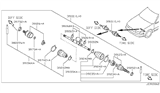

- Q: What is the transmission of power from the transaxle to the wheels and how can wear in the CV joints and driveaxle shafts be checked on Nissan Sentra?A:Power is transmitted from the transaxle to the wheels through a pair of axle shafts. The inner end of each axle shaft is splined into the differential side gears. The outer ends of the axle shafts are splined to the axle hubs and locked in place by a large nut. The inner ends of the axle shafts are equipped with tripod-type constant velocity joints which are capable of both angular and axial motion. The outer CV joints are the ball and cage type. The boots should be inspected periodically for damage and leaking lubricant. Torn CV joint boots must be replaced as soon as possible or the joints can be damaged. Boot replacement involves removal of the axle shaft. The most common symptom of worn or damaged CV joints, besides lubricant leaks, is a clicking noise in turns, a clunk when accelerating after coasting and vibration at highway speeds. To check for wear in the CV joints and axle shaft shafts, grasp each axle (one at a time) and rotate it in both directions while holding the CV joint housings, feeling for play indicating worn splines or sloppy CV joints.

Related Nissan Sentra Parts

Browse by Year

2025 Axle Shaft 2024 Axle Shaft 2023 Axle Shaft 2022 Axle Shaft 2021 Axle Shaft 2020 Axle Shaft 2019 Axle Shaft 2018 Axle Shaft 2017 Axle Shaft 2016 Axle Shaft 2015 Axle Shaft 2014 Axle Shaft 2013 Axle Shaft 2012 Axle Shaft 2011 Axle Shaft 2010 Axle Shaft 2009 Axle Shaft 2008 Axle Shaft 2007 Axle Shaft 2006 Axle Shaft 2005 Axle Shaft 2004 Axle Shaft 2003 Axle Shaft 2002 Axle Shaft 2001 Axle Shaft 2000 Axle Shaft 1999 Axle Shaft 1998 Axle Shaft 1997 Axle Shaft 1996 Axle Shaft 1995 Axle Shaft 1994 Axle Shaft 1993 Axle Shaft 1992 Axle Shaft 1991 Axle Shaft 1990 Axle Shaft 1989 Axle Shaft 1988 Axle Shaft 1987 Axle Shaft 1986 Axle Shaft 1985 Axle Shaft 1984 Axle Shaft 1983 Axle Shaft 1982 Axle Shaft