×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

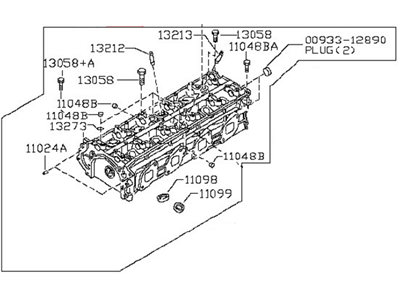

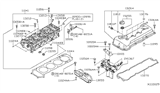

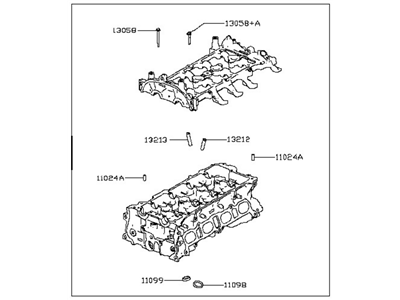

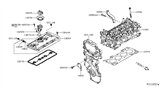

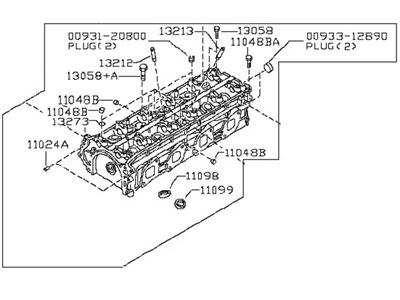

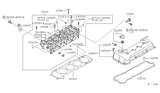

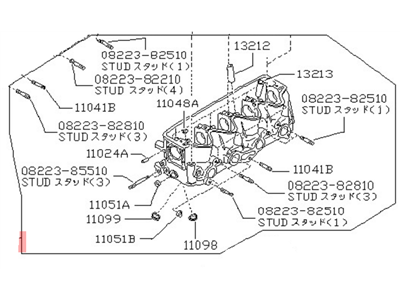

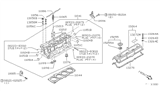

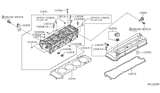

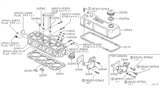

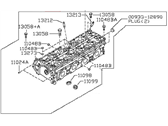

Genuine Nissan Sentra Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

35 Cylinder Heads found

Nissan Sentra Cylinder Head Assembly

Part Number: 11040-JA00A$1275.73 MSRP: $1617.03You Save: $341.30 (22%)Ships in 1-2 Business DaysNissan Sentra Cylinder Head Assembly

Part Number: 11040-3RC1B$941.35 MSRP: $1329.58You Save: $388.23 (30%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head Assembly

Part Number: 11040-6LB0A$1060.83 MSRP: $1498.35You Save: $437.52 (30%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head Assembly

Part Number: 11040-BV80A$1654.14 MSRP: $2002.59You Save: $348.45 (18%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head Assembly

Part Number: 11040-8H301$764.32 MSRP: $996.51Limited AvailabilityYou Save: $232.19 (24%)Nissan Sentra Cylinder Head Assembly

Part Number: 11040-EL00A$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head

Part Number: 11040-ZJ80B$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head

Part Number: 11040-ZJ80A$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Sentra Cylinder Head

Part Number: 11041-31M00$832.36 MSRP: $1085.22Limited AvailabilityYou Save: $252.86 (24%)Nissan Sentra Cylinder Head Assembly

Part Number: 11040-6M400$400.60 MSRP: $538.87Limited AvailabilityYou Save: $138.27 (26%)Nissan Sentra Cylinder Head

Part Number: 11040-ZJ80C$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Sentra Head Cylinder

Part Number: 11041-21M02$766.91 MSRP: $999.88Limited AvailabilityYou Save: $232.97 (24%)Nissan Sentra Head Cylinder

Part Number: 11041-21M01$766.91 MSRP: $999.88Limited AvailabilityYou Save: $232.97 (24%)Nissan Sentra Head Cylinder

Part Number: 11041-21M00$766.91 MSRP: $999.88Limited AvailabilityYou Save: $232.97 (24%)Nissan Sentra Cylinder Head

Part Number: 11041-31M01$832.36 MSRP: $1085.22Limited AvailabilityYou Save: $252.86 (24%)Nissan Sentra Cylinder Head Assembly

Part Number: 11040-6LB1A$1060.83 MSRP: $1498.35You Save: $437.52 (30%)

| Page 1 of 2 |Next >

1-20 of 35 Results

Nissan Sentra Cylinder Head

If you need any OEM Nissan Sentra Cylinder Head, feel free to choose them out of our huge selection of genuine Nissan Sentra Cylinder Head. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Sentra Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install a cylinder head in an engine on Nissan Sentra?A:Disconnect the multiselector/fuel rail pressure signal adaptor quick-connect and remove the snap ring, then have the engine at TDC compression for cylinder no. 1. Remove the cooling system fluid and take out the Timing Chain; the camshafts and the exhaust and Intake Manifolds. Anyone remaining items connected to the cylinder head should be removed and labeled appropriately-coolant fittings/tubes, cables, hoses, or wiring harnesses inclusive. Attach a breaker bar to the appropriate-size hex bit in cylinder head bolts and turn them counterclockwisely in 1/4 turn until they can be removed by hand; apply the reverse of the above process to avoid warping or cracking of cylinder head. Raise up the cylinder head off of the engine block with, perhaps, some force if it is tightly fixed in place. Take out all the bolts from the C/cylinder head so that it is externally clean and dismantled for inspection. The surfaces of the cylinder head and the block which are required to mate have to be free from dirt before they are placed together. Gasket scraper has to be used to scrape off the carbon and the old the gasket material while the surfaces to be mated have to be wiped with the lacquer thinner or acetone, making sure there is no oil that may hinder proper sealing of the gasket. Pack the cylinders with clean shop rags to reduce the chance of bringing in new material so use a vacuum cleaner to clean all the cylinders. Inspect all the flat surfaces of the block and the cylinder head for any signs of nicks, scratch marks or the like or use a fine file if there is mild or use the machining service if there is severe damage. You should change the tap to one that will chase the threads in the cylinder head bolt holes, and blow off the holes with compressed air. When the gasket surface of the cylinder head is cleaned, ensure that it is warping and look at the cylinder head gasket, intake, and Exhaust Manifold. Bolt any components that were removed from the Cylinder head; align any new cylinder head gasket over the dowel pin in the block; and gently lay the Cylinder head on the block over the gasket. Before tightening a new cylinder head, bolts must be lubricated with a clean engine oil where the threads and the hardened washers are passed through the chamfered side of the washers facing the head of the bolts. Replace the new cylinder head bolts and correctly tighten them in the advised sequence to the right torque. The lifters have to be put into position together with the camshafts, and the timing chain has to go on next the valve clearances have to be checked. The rest of the installation procedure is, of course, the exact opposite to the removal process. Replace the coolant that has lost opacity, replace the oil filter, and put some oil in the engine. Finally, connect the battery , and those of you who are interested in some of the re-learn procedures, turn the Ignition switch on.

Related Nissan Sentra Parts

Browse by Year

2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1986 Cylinder Head 1985 Cylinder Head 1984 Cylinder Head 1983 Cylinder Head 1982 Cylinder Head