×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Versa Spark Plug

Ignition Spark Plug- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Spark Plugs found

Nissan Versa Spark Plug

Part Number: 22401-1HC1B$16.93 MSRP: $24.52You Save: $7.59 (31%)Ships in 1-3 Business Days

Nissan Versa Spark Plug

Part Number: 22401-JD01B$20.40 MSRP: $29.55You Save: $9.15 (31%)Ships in 1-3 Business Days

Nissan Versa Spark Plug

Part Number: 22401-5RL1B$34.21 MSRP: $49.55You Save: $15.34 (31%)Ships in 1-3 Business Days

Nissan Versa Spark Plug

Part Number: 22401-1KT1B$23.58 MSRP: $34.15You Save: $10.57 (31%)Ships in 1-3 Business DaysNissan Versa Spark Plugs

Part Number: 22401-ED71B$17.83 MSRP: $35.88You Save: $18.05 (51%)Ships in 1-3 Business DaysNissan Versa Spark Plug

Part Number: 22401-ED71A$24.38 MSRP: $35.32You Save: $10.94 (31%)Ships in 1-3 Business DaysNissan Versa Spark Plugs

Part Number: 22401-EW61B$20.40 MSRP: $29.55You Save: $9.15 (31%)Ships in 1-3 Business Days

Nissan Versa Spark Plug

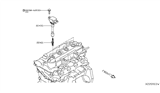

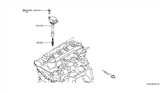

Spark Plug is one of the highly important parts that have a direct impact on the durability and efficiency of Nissan's compact car brand. A replaceable wedge Spark Plug that was specifically manufactured to efficiently facilitate ignition of the air-fuel mixture found within the combustion chamber of Nissan Versa engines is called the Spark Plug. It is available in different types including copper/nickel, platinum, and iridium, and can be applied in Nissan Versa S, SV, and SL. Selecting the ideal Spark Plug is vital because of the likely influence on the performance, fuel efficiency, and security of the car. A well-functioning Spark Plug means there will be no accidents of misfires and the Versa clocking an impressive fuel economy when equipped with a CVT. In the same regard, the Spark Plug is also an important aspect that helps the lifetime of a car thus distinguishing it in the market. Due to enhancing the reliability, performance together with the compatibility of the Spark Plug to different Versa models, it contributes significantly to the effective safety and efficiency of Nissan, thus putting it as a dependable automobile type for compact car users.

If you need any OEM Nissan Versa Spark Plug, feel free to choose them out of our huge selection of genuine Nissan Versa Spark Plug. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa Spark Plug Parts Questions & Experts Answers

- Q: What tools and steps are required for spark plug replacement on Nissan Versa?A:Spark plug replacement requires a spark plug socket and extension that fit onto a ratchet, with the socket lined with a rubber grommet to protect the porcelain insulator and hold the plug during removal. A wire-type feeler gauge is needed to check and adjust the spark plug gap, along with a torque wrench to tighten the new plugs to the specified torque. The gap can only be checked, and if incorrect, the spark plug must be replaced. When replacing plugs, purchase new ones, check for proper gap, and replace each plug one at a time, inspecting for defects such as cracks in the porcelain insulator. The electrode gaps should be checked using the wire gauge, ensuring the gap is identical to the recommended specification; if not, the spark plug must be replaced. If the side electrode is not aligned with the center electrode, the spark plug should also be replaced. During removal, clear any dirt from the ignition coil area with compressed air, remove the ignition coils, and then use the spark plug socket with a ratchet and extension to take out the spark plugs. Compare each old spark plug with a provided chart to assess the engine's overall running condition. For installation, apply a thin coat of anti-seize compound to the plug threads, avoiding the lower threads, and use a snug-fitting rubber hose over the spark plug to prevent cross-threading. Tighten the plug to the specified torque and repeat the process for the remaining plugs. After replacing all plugs, reinstall the ignition coils and, for certain models, the intake manifold.

Related Nissan Versa Parts

Browse by Year

2025 Spark Plug 2024 Spark Plug 2023 Spark Plug 2022 Spark Plug 2021 Spark Plug 2020 Spark Plug 2019 Spark Plug 2018 Spark Plug 2017 Spark Plug 2016 Spark Plug 2015 Spark Plug 2014 Spark Plug 2013 Spark Plug 2012 Spark Plug 2011 Spark Plug 2010 Spark Plug 2009 Spark Plug 2008 Spark Plug 2007 Spark Plug