×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Xterra Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

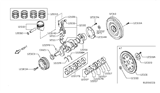

4 Crankshafts found

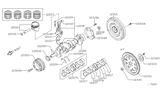

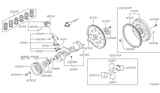

Nissan Xterra Crankshaft Assembly

Part Number: 12200-EA200$1026.43 MSRP: $1449.77You Save: $423.34 (30%)Ships in 1-3 Business DaysNissan Xterra Crankshaft Assembly

Part Number: 12200-9BF0A$1026.43 MSRP: $1449.77You Save: $423.34 (30%)

Nissan Xterra Crankshaft

If you need any OEM Nissan Xterra Crankshaft, feel free to choose them out of our huge selection of genuine Nissan Xterra Crankshaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Xterra Crankshaft Parts Questions & Experts Answers

- Q: How do you properly reassemble and install the crankshaft during the engine reassembly process on Nissan Xterra?A:The reassembly of an engine must begin with thorough cleaning, inspection, and repair or reconditioning of the engine block and crankshaft. The engine should be positioned such that the crankcase faces upwards on the stand. The brace assembly must be lifted out of the bearing cap through removal of main bearing cap bolts and ensure no harm comes to bearing surfaces. If it exists, take out original bearing inserts from both main caps and block and clean their surfaces using a lint free cloth. Keep the surfaces precisely clean. For the following check for main bearing oil clearance, place new main bearing inserts into main bearing saddles in block ensuring proper alignment with oil holes in a block. Bear in mind that bearings should not be hammered into position as this may damage bearing faces. Place the flanged thrust bearing without lubrication either behind it or at its front face depending on the kind of engine (fourth cap and saddle for 3.3L engines) (third cap and saddle for 2.4L and 3.5L engines). Ensure cleanliness of both these surfaces as well as those on the crankshaft main bearing journals. Once cleaned, laydown the crankshaft within the primary bearings at their places relative to each other Next important step is to use Plastigage for checking main bearing oil clearance on each crankshaft journal.Remove any traces of Plastigage from the journals before installing them which should face towards drivebelt end Install brace assemblies with caps by tightening bolts until Plastigage is not disturbed in accordance with arrow directions Rotate gradually tightening main-bearing cap assembly bolts three times starting from centre going outwards avoiding turning over crankshaft After tightening all these bolts to required torque remove caps carefully leaving Plastigage untouched Measure crushed width against scale on envelope to determine if specified value meets up with clearance specified If not ensure cleanliness then think about probably changing such things like different types of inserts used Carefully remove all Plastigage material traces from bearing faces and main bearing journals The crankshaft should be put into the block with clean caps and then the cap bolts tightened to torque values Aligning main bearing and crankshaft thrust surfaces by gently tapping ends of the crankshafts After re-tightening all main-bearing cap bolts, rotate crankshaft by hand in order to check for any binding Verify the amount of endplay in the crankshaft using feeler gauge or dial indicator, if new bearings are installed and thrust faces are good Finally, secure it to block when installing a new seal and retainer.