×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Juke Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Drive Shaft found

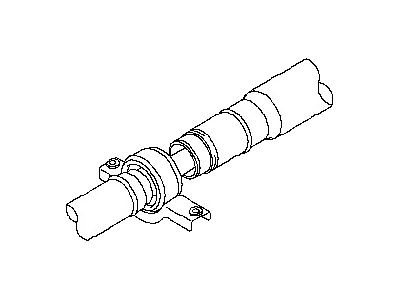

Nissan Juke Shaft Assembly Propeller

Part Number: 37000-1KA0A$1443.32 MSRP: $1747.36You Save: $304.04 (18%)Ships in 1-3 Business Days

Nissan Juke Drive Shaft

Drive Shaft is a shaft set that we identified as being dependent for its durability and efficiency in the Nissan Juke series. Acting primarily as the mechanical power and torque take-off between the engine and the drive wheels, Drive Shaft plays a critical role in the movement of cars besides increasing efficiency and safety of the vehicles. Built to take torsion and shear stress, yet light the Drive Shaft's construction helps to decrease inertia which is beneficial for the car handling. Different models of Nissan Juke employ usage of one-piece and two-piece Drive Shaft of which the later offers a better crash safety. Nissan, in the frame of Juke, offers all sorts of all-wheel drive layouts in which there is just one Drive Shaft connected to the rear axle in order to prove the flexibility of the company's drivetrain concept. The Drive Shaft enables the car user to get the optimal performance regardless of the variations of the different Juke models. In this regard, the Juke Drive Shaft also uses universal or splined joints to adjust for alignment, making the unit very dependable. Thus, the Nissan Juke equipped with the unique design and the efficiency of the Drive Shaft can be classified as an innovative automobile model in the contemporary automotive world. Thus, the Drive Shaft can be still considered as the crucial part in control and driving of the car with performance, safety and efficiency playing the key role for making the Juke as leading compact crossover SUV.

If you need any OEM Nissan Juke Drive Shaft, feel free to choose them out of our huge selection of genuine Nissan Juke Drive Shaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Juke Drive Shaft Parts Questions & Experts Answers

- Q: How to check and replace the driveshaft components on Nissan Juke?A:Check that the driveshaft nut is correctly tightened; if in doubt, remove the split-pin. Check that the nut is tightened to the specified torque, and then refit a new split-pin. Refit the roadwheel trim or centre cap (as applicable), and repeat the check on the remaining driveshaft nut. Road test the vehicle, and listen for a metallic clicking from the front as the vehicle is driven slowly in a circle on full-lock. If a clicking noise is heard, this indicates wear in the outer constant velocity joint. If vibration, consistent with roadspeed, is felt through the car when accelerating, there is a possibility of wear in the inner constant velocity joints. To check the joints for wear, remove the driveshafts, then dismantle them. If any wear or free play is found, the relevant joint, or joint components must be renewed. Note that the inner constant velocity joints are not available separately and if worn a new driveshaft(s) will be required. Remove the right-hand front driveshaft. If the bearing housing was removed with the driveshaft, the shaft will need to be carefully pressed from the housing. Note the fitted position of the metal dust cap, and then remove it from the inner end of the driveshaft. Remove the metal shield from the bearing, and then using circlip pliers, remove the circlip from the driveshaft. Using a long puller withdraw the bearing from the driveshaft. Fit the new bearing onto the driveshaft and carefully tap it into position on the shaft. Fit the new circlip making sure it is located in the groove in the shaft. Fit the new metal shield onto the driveshaft and carefully tap it into position on the shaft. Fit the new metal dust cap onto the driveshaft and carefully tap it into the position noted on removal. Where applicable bolt the bearing housing to the rear of the cylinder block, then refit the driveshaft.