×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Wheel Seal

Wheel Axle Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Wheel Seals found

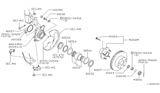

Nissan Maxima Seal Hub

Part Number: 40232-33P00$15.55 MSRP: $27.02You Save: $11.47 (43%)Ships in 1-3 Business Days

Nissan Maxima Seal Hub

Part Number: 40232-33P10$19.13 MSRP: $27.02You Save: $7.89 (30%)Ships in 1-3 Business DaysNissan Maxima Seal-Grease Hub

Part Number: 40232-06R10$12.85 MSRP: $17.72Limited AvailabilityYou Save: $4.87 (28%)Nissan Maxima Seal-Grease Hub

Part Number: 40232-06R00$12.85 MSRP: $17.72Limited AvailabilityYou Save: $4.87 (28%)Nissan Maxima Seal-Grease Hub

Part Number: 40232-01E01$12.85 MSRP: $17.72Limited AvailabilityYou Save: $4.87 (28%)

Nissan Maxima Wheel Seal

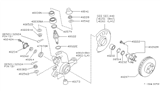

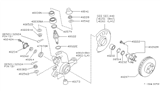

It is important to note that the Nissan Maxima Wheel Seal is among those crucial parts that speak for the Nissan Maxima series. The function of bearing special protection of the wheel bearing and hub against detrimental influences of environmental contaminants, the Wheel Seal is a critical component of the wheel assembly. As a result of stopping the seepage of lubricants and exclusion of invasions by undesirable matter, the Nissan Maxima Wheel Seal contributes to supplying lubricants adequately, which is a significant method towards avoiding high temperatures that make the metal brittle. This reliability is much valued across the different Maxima models since this Wheel Seal comes with different abilities to fit front and rear inner and outer seals besides the complete sets. Every Nissan Maxima Wheel Seal is made using quality materials by standard suppliers so that it will fit well and last longer on the car. Hence, Wheel Seal's function is not just a mere aesthetic add-on but an essential feature that improves the efficiency and general safety of the vehicle, makeup the rides more enjoyable. However, it should be noted that the Nissan Maxima Wheel Seal is considered to be relatively Rock solid in the market and is designed to fit multiple generations of the Maxima, so it can be regarded as the prime fit for both the car enthusiasts as well as for the average car users. This long lasting wheel seal is living proof as to why Nissan is at the top when it comes to creating great, reliable vehicles with innovative features to complement the sporty elegance of the Maxima, unfailingly establishing its place in the segment of fantastic luxury sports sedans.

If you need any OEM Nissan Maxima Wheel Seal, feel free to choose them out of our huge selection of genuine Nissan Maxima Wheel Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Wheel Seal Parts Questions & Experts Answers

- Q: How can you replace oil seals and O-rings on Nissan Maxima?A:Some oil leaks arise from worn seals or O-rings and replacement of these parts is usually easy and does not necessarily require that the transaxle be pulled out from the car. Driveaxle oil seals are mounted at the sides of the transaxle, directly on the driveaxles at the place where the side gears of the differential are connected. To verify the leaking driveaxle oil seal, the vehicle has to be lifted on jackstands and lubricant is usually visible at the transaxle bottom of the seal. To replace the seal, one has to first take out the driveaxle, followed by using a seal removal tool, or a screwdriver to pry out the old seal out of the bore, without causing any harm to the bore. Use a large pipe or deep socket to set this new oil seal in flush and rightly on the shaft or the housing, and after installing the new seal, put some multi-purpose grease on the lip of the new seal and after doing this, refit the or driveaxle carefully without applying any force on the new seal that might harm the lip. Also damaged is the vehicle speed sensor situated in the transaxle housing; notice leakage around the O-ring then unbolt the electrical connector, remove the hold-down bolt to retrieve the pinion assembly and sensor. Take out the old O-ring using the scribe, or a small screwdriver and fit a new O-ring to the pinion gear housing and before its fixing, apply on the sensor end of it some drops of the transmission fluid. For the control rod seal, lift the vehicle and detach the control rod from the yoke, then, remove the yoke retaining pin, yoke and finally, the dust boot to access the control rod seal to effect a change or replacement. Once the new seal has been inserted, replace the yoke and the retaining pin and connect the shaft of the control rod and then lower the vehicle.