×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Murano Drive Shaft

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Drive Shafts found

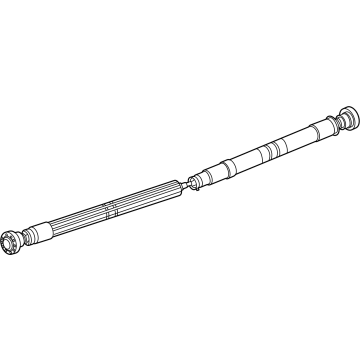

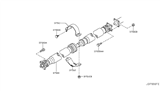

Nissan Murano Propeller Shaft Assembly

Part Number: 37000-1AA1A$906.18 MSRP: $1279.92You Save: $373.74 (30%)Ships in 1-3 Business Days

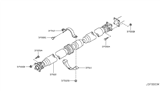

Nissan Murano Shaft Assembly Propeller

Part Number: 37000-CB00A$707.97 MSRP: $1046.95You Save: $338.98 (33%)Ships in 1-2 Business Days

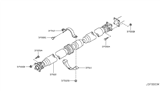

Nissan Murano Propeller Shaft Assembly

Part Number: 37000-CA000$1125.12 MSRP: $1589.15You Save: $464.03 (30%)Ships in 1-3 Business DaysNissan Murano Shaft Assembly Propeller

Part Number: 37000-5AA1B$783.82 MSRP: $1107.08You Save: $323.26 (30%)Ships in 1-3 Business DaysNissan Murano Propeller Shaft Assembly

Part Number: 37000-1AA0A$906.18 MSRP: $1279.92You Save: $373.74 (30%)Ships in 1-3 Business DaysNissan Murano Propeller Shaft Assy

Part Number: 37000-5AA0A$783.82 MSRP: $1107.08You Save: $323.26 (30%)Ships in 1-3 Business DaysNissan Murano Propeller Shaft Assembly

Part Number: 37000-CB000$741.24 MSRP: $1046.95You Save: $305.71 (30%)Ships in 1-3 Business DaysNissan Murano PROPELLER SHAFT ASSY

Part Number: 37000-7BA0A$538.17 MSRP: $760.13You Save: $221.96 (30%)

Nissan Murano Drive Shaft

If you need any OEM Nissan Murano Drive Shaft, feel free to choose them out of our huge selection of genuine Nissan Murano Drive Shaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

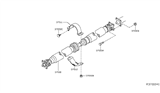

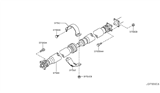

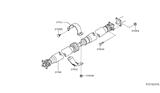

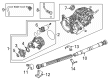

Nissan Murano Drive Shaft Parts Questions & Experts Answers

- Q: What are the key inspection and maintenance steps for a driveshaft and Universal Joints, and what signs indicate potential issues on Nissan Murano?A:In these vehicles, the driveshaft comprises of two tubes, which transmit power from the Transfer Case to the rear Differential; at the extremity of the tubes, standard universal joints are employed; in the middle, a constant velocity joint that is overlaid with a bearing is installed. This assembly is virtually self-service since the universal joints are supplied with lubricant for the life of the assembly and if, for some reason a part fails, the only solution is replacement of the entire driveshaft although some specialty shops may offer rebuilding services. The driveshaft must be cleansed and should not have any traces of undercoating or mud; checking for damages when the car is in the raised position for service, see that the tiny balancing weights are also intact. Most problems are identified in terms of noise or vibration, and this can be tested while on the road. To examine the driveshaft safely get the car off the ground using jackstands, Also lock the wheels, disengage the parking brake and shift the transaxle to Neutral. Check for any dents or cracks on the drive shaft and if the situation is severe go for a new drive shaft. Look for signs of oil leak from the front and rear area, it is a sign of a bad seal and check for the rear driveaxles joint for looseness. Turn the driveshaft around to check the universal joints and make sure that they do not lock up or squeak, also apply the stethoscope to check the center bearing for any sound of wear. Grasp each joint with the hands and try to twist to ensure that there is relative motion which indicates that it is heavily worn out also ensure that mounting bolts and nuts are tight. Last but not the least, check the condition of the center bearing; whether it has come loose or the rubber has perished; see that the bracket holding the bearing is not bent.

Related Nissan Murano Parts

Browse by Year

2025 Drive Shaft 2024 Drive Shaft 2023 Drive Shaft 2022 Drive Shaft 2021 Drive Shaft 2020 Drive Shaft 2019 Drive Shaft 2018 Drive Shaft 2017 Drive Shaft 2016 Drive Shaft 2015 Drive Shaft 2014 Drive Shaft 2013 Drive Shaft 2012 Drive Shaft 2011 Drive Shaft 2010 Drive Shaft 2009 Drive Shaft 2008 Drive Shaft 2007 Drive Shaft 2006 Drive Shaft 2005 Drive Shaft 2004 Drive Shaft 2003 Drive Shaft