×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Crankshaft Seals found

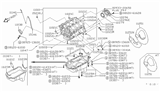

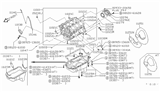

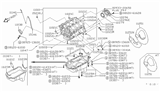

Nissan Quest Seal-Oil,Crankshaft Front

Part Number: 13510-31U10$17.44 MSRP: $24.63You Save: $7.19 (30%)Ships in 1-3 Business Days

Nissan Quest Seal-Oil,Crankshaft Front

Part Number: 13510-7Y000$25.74 MSRP: $36.35You Save: $10.61 (30%)Ships in 1-2 Business Days

Nissan Quest Seal-Oil,Crankshaft Front

Part Number: 13510-9HP0A$15.83 MSRP: $21.82You Save: $5.99 (28%)Ships in 1-3 Business Days

Nissan Quest Retainer Assy-Oil Seal,Rear

Part Number: 12296-JA10A$37.81 MSRP: $52.12You Save: $14.31 (28%)Ships in 1-3 Business Days

Nissan Quest Retainer Assy-Oil Seal,Rear

Part Number: 12296-31U20$56.00 MSRP: $79.10You Save: $23.10 (30%)Ships in 1-3 Business Days

Nissan Quest Seal-Oil,Crankshaft Front

Part Number: 13510-10Y10$12.71 MSRP: $17.52You Save: $4.81 (28%)Ships in 1-2 Business Days

Nissan Quest Seal-Oil,CRANKSHAFT Rear

Part Number: 12279-4Z001$37.40 MSRP: $54.17You Save: $16.77 (31%)Ships in 1-2 Business Days

Nissan Quest Retainer Assy-Oil Seal,Rear

Part Number: 12296-9HP0A$47.19 MSRP: $65.05You Save: $17.86 (28%)Ships in 1-2 Business Days

Nissan Quest RETAINER-Oil

Part Number: 12297-F6500$43.51 MSRP: $59.98You Save: $16.47 (28%)Ships in 1-2 Business Days

Nissan Quest Seal-Oil,CRANKSHAFT Rear

Part Number: 12279-18V00$35.05 MSRP: $50.77You Save: $15.72 (31%)Ships in 1-2 Business Days

Nissan Quest Seal-Oil,CRANKSHAFT Rear

Part Number: 12279-1E000$39.48 MSRP: $57.18You Save: $17.70 (31%)

Nissan Quest Seal-Oil,CRANKSHAFT Rear

Part Number: 12279-30P00$35.05 MSRP: $50.77You Save: $15.72 (31%)Nissan Quest Seal-Oil, CRANKSHAFT Rear

Part Number: 12279-55Y00$29.01 MSRP: $42.02You Save: $13.01 (31%)Ships in 1-2 Business Days

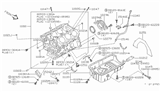

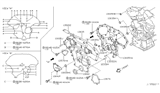

Nissan Quest Crankshaft Seal

If you need any OEM Nissan Quest Crankshaft Seal, feel free to choose them out of our huge selection of genuine Nissan Quest Crankshaft Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Crankshaft Seal Parts Questions & Experts Answers

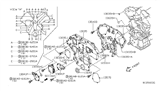

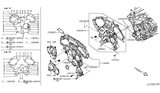

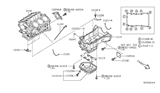

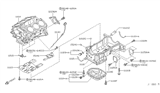

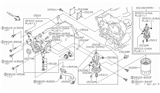

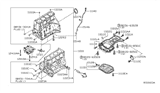

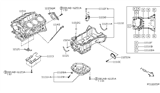

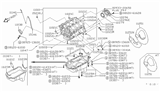

- Q: How to install a Crankshaft Seal, including the steps for removing the old seal, preparing the new seal on Nissan Quest?A:An interesting aspect is the one-piece sealing system that is put into a housing located at the transaxle extension of the block; an element where the Crankshaft is inserted prior to engaging the main bearing caps and, in fact, where the new Crankshaft Seal is fitted into the retainer and bolted to the block. Again, the seal contact surface needs to be checked for any roughness due to scratching causing the trim on the new seal lip and eventual oil leakage; if the crankshaft is badly worn, advice to get a replacement. The old seal can be easily chased out using hammer and punch from the back side of the retainer by noting down the depth; it is to be remembering that while fitting the new Crankshaft Seal this depth is required to be followed to without causing any harm to the bore in the retainer that results in the leakage of oil. Once the retainer has been cleaned, a thin layer of engine oil is then applied to the outer periphery of the new seal which has to be fitted squarely into the retainer bore, if a press is not available, then the retainer and the seal can be put in between two identical wooden blocks and the vise is applied till the force is evenly distributed and the seal is properly aligned with the retainer so that the them being pressed together Lubricate both sides of the seal lips with moly-base grease or engine assembly lube or before placing of the seal/retainer over the crankshaft is done then it should be firmly fit into the block and a new gasket should be used without sealant, the dowel pins should also be put before fitting the seal/retainer. Last of all the screws should be tightened in sequence to approximately the tightening torque decided upon.

Related Nissan Quest Parts

Browse by Year

2017 Crankshaft Seal 2016 Crankshaft Seal 2015 Crankshaft Seal 2014 Crankshaft Seal 2013 Crankshaft Seal 2012 Crankshaft Seal 2011 Crankshaft Seal 2010 Crankshaft Seal 2009 Crankshaft Seal 2008 Crankshaft Seal 2007 Crankshaft Seal 2006 Crankshaft Seal 2005 Crankshaft Seal 2004 Crankshaft Seal 2003 Crankshaft Seal 2002 Crankshaft Seal 2001 Crankshaft Seal 2000 Crankshaft Seal 1999 Crankshaft Seal 1998 Crankshaft Seal 1997 Crankshaft Seal 1996 Crankshaft Seal 1995 Crankshaft Seal 1994 Crankshaft Seal 1993 Crankshaft Seal