×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

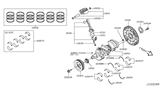

7 Crankshafts found

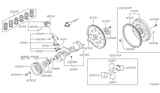

Nissan Quest Crankshaft Assembly

Part Number: 12200-7Y00A$228.50 MSRP: $322.73You Save: $94.23 (30%)Ships in 1-3 Business DaysNissan Quest Crankshaft Assembly

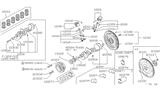

Part Number: 12200-JA11A$1309.07 MSRP: $1584.83You Save: $275.76 (18%)Ships in 1-3 Business Days

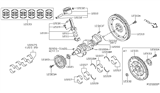

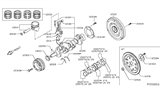

Nissan Quest Crankshaft

If you need any OEM Nissan Quest Crankshaft, feel free to choose them out of our huge selection of genuine Nissan Quest Crankshaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed on Nissan Quest?A:The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that the driveplate, crankshaft pulley, timing belt, sprocket, oil pan, oil pump, and piston/connecting rod assemblies have already been detached. Before removing the crankshaft, check the endplay by mounting a dial indicator with the stem aligned with the crankshaft and touching one of the crank throws. Push the crankshaft to the rear and zero the dial indicator, then pry it to the front and check the reading to determine the endplay. If it exceeds the specified limit, inspect the crankshaft thrust surfaces for wear; if no wear is found, new main bearings should resolve the issue. If a dial indicator is unavailable, feeler gauges can be used by prying or pushing the crankshaft to the front and slipping the gauges between the crankshaft and the front face of the rear main bearing to measure clearance. The main bearing cap assembly features a cast-in arrow pointing to the timing belt end of the engine; loosen the cap bolts gradually until the assembly can be removed by hand, ensuring to follow the reverse of the tightening sequence. Gently tap the cap assembly with a soft-face hammer to separate it from the engine block, using the bolts as levers if necessary, and take care not to drop the bearing inserts. Finally, carefully lift the crankshaft out of the engine, ideally with assistance due to its weight, and return the cap assembly to its location on the engine block, tightening the bolts finger tight.

Related Nissan Quest Parts

Browse by Year

2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft 1994 Crankshaft 1993 Crankshaft