×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

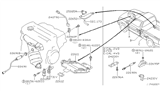

Genuine Nissan Quest Knock Sensor

Engine Knock Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Knock Sensors found

Nissan Quest Sensor Assembly-Knock

Part Number: 22060-30P00$219.63 MSRP: $325.20You Save: $105.57 (33%)Ships in 1-2 Business Days

Nissan Quest Knock Sensor

Part Number: 22060-7S000$139.07 MSRP: $205.92You Save: $66.85 (33%)Ships in 1-3 Business Days

Nissan Quest Knock Sensor

Part Number: 22060-7B000$228.58 MSRP: $338.47You Save: $109.89 (33%)Ships in 1-2 Business DaysNissan Quest Sensor Assembly Knock

Part Number: 22060-JK20C$291.19 MSRP: $444.43You Save: $153.24 (35%)Ships in 1-3 Business DaysNissan Quest Knock Sensor

Part Number: 22060-AU010$139.07 MSRP: $205.92You Save: $66.85 (33%)Ships in 1-3 Business Days

Nissan Quest Knock Sensor

If you need any OEM Nissan Quest Knock Sensor, feel free to choose them out of our huge selection of genuine Nissan Quest Knock Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Knock Sensor Parts Questions & Experts Answers

- Q: How do knock sensors detect abnormal vibration in the engine and How to check and replace them on Nissan Quest?A:Knock sensors detect abnormal vibration in the engine and are part of a control system designed to reduce spark knock during heavy detonation, allowing for maximum spark advance to enhance driveability. These sensors produce AC output voltage that increases with the severity of the knock, sending a signal to the PCM to retard timing in response to severe detonation. To check a knock sensor, disconnect the KS sub-harness electrical connector located on the passenger side of the engine compartment next to the intake manifold. Use a voltmeter set to the lowest AC voltage scale, connecting the negative probe to ground and the positive probe to the sensor terminal on the sub-harness connector, typically identified by a white wire. Tap sharply on the intake manifold to simulate engine knock and observe voltage fluctuations; if none are detected, the sensor is faulty and needs replacement. To replace the sensor, remove the upper and lower intake manifold and the coolant crossover tube, unplug the electrical connector, and take out the sensor retaining bolt and the sensor from the engine block. Install the new sensor, tightening the retaining bolt to 18 to 25 ft-lbs, reconnect the electrical connector, and reinstall the intake manifold, refilling the cooling system as necessary.

Related Nissan Quest Parts

Browse by Year

2017 Knock Sensor 2016 Knock Sensor 2015 Knock Sensor 2014 Knock Sensor 2013 Knock Sensor 2012 Knock Sensor 2011 Knock Sensor 2010 Knock Sensor 2009 Knock Sensor 2008 Knock Sensor 2007 Knock Sensor 2006 Knock Sensor 2005 Knock Sensor 2004 Knock Sensor 2003 Knock Sensor 2002 Knock Sensor 2001 Knock Sensor 2000 Knock Sensor 1999 Knock Sensor 1998 Knock Sensor 1997 Knock Sensor 1996 Knock Sensor 1995 Knock Sensor 1994 Knock Sensor 1993 Knock Sensor