×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest Mass Air Flow Sensor

MAF Sensor Meter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Mass Air Flow Sensors found

Nissan Quest Air Flow Sensor

Part Number: 22680-7S000$220.69 MSRP: $326.77You Save: $106.08 (33%)Ships in 1-2 Business Days

Nissan Quest Mass Air Flow Sensor Maf Sensor

Part Number: 22680-3VA0A$233.82 MSRP: $346.22You Save: $112.40 (33%)Ships in 1-3 Business Days

Nissan Quest Mass Air Flow

Part Number: 22680-CA000$263.62 MSRP: $402.35You Save: $138.73 (35%)Ships in 1-2 Business Days

Nissan Quest Mass Air Flow Sensor

Part Number: 22680-7B001$250.51 MSRP: $370.93You Save: $120.42 (33%)Ships in 1-3 Business Days

Nissan Quest Mass Air Flow

Part Number: 22680-7B000$250.51 MSRP: $370.93You Save: $120.42 (33%)Ships in 1-3 Business Days

Nissan Quest Mass Air Flow Sensor

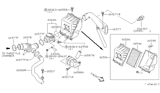

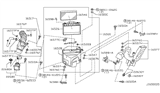

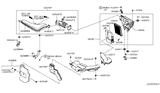

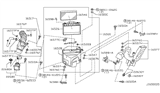

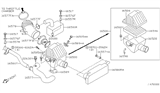

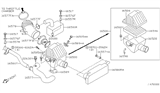

In Quest vehicles, the Mass Air Flow Sensor (MAF) functions as the key controller which measures engine air intake to support maximum engine performance. The measurements from the Mass Air Flow Sensor send information to the powertrain control module (PCM) to control fuel injection as the PCM works to keep the air/fuel ratio accurate. Both vane meters (VAF) alongside hot wire sensors represent different types of Quest Mass Air Flow Sensor applied in automotive systems. The VAF sensor maintains effective results although it faces restrictions in air passage and requires maintenance while the hot wire sensor provides precise measurement until substances contaminate its operation. Among Quest Mass Air Flow Sensor options, hot film and karman vortex sensors are available in addition to existing varieties that measure airflow using separate methodologies. All Nissan MAF sensors require proper maintenance to protect against automobile problems that can develop into diagnostic trouble codes and check engine light alerts. Proper care of Nissan's Mass Air Flow Sensor is essential for optimal vehicle performance. Regular checks and maintenance of Nissan's MAF sensors can prevent issues that may lead to engine inefficiency.

If you need any OEM Nissan Quest Mass Air Flow Sensor, feel free to choose them out of our huge selection of genuine Nissan Quest Mass Air Flow Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Mass Air Flow Sensor Parts Questions & Experts Answers

- Q: How do you test, diagnose, and replace a Mass Air flow sensor on Nissan Quest?A:If in a testing of the sensor an individual discovers that the sensor is in good condition and its functioning is not causing a specific driveability problem, the wiring harness and the connectors situated between the sensor and the PCM should also be checked for open or short circuits. If no problems are identified, take the car to a dealer service department or an authorized auto repair shop. The Mass Airflow (MAF) sensor is fitted in the air intake duct Take for instance, the hot-wire sensing elements that is used to determine the molecular mass of air inflow into the engine. As air is over the hot wire it cools and this change in temperature is converted into an analog voltage signal to the PCM the PCM in turn calculates pulse width of the fuel injector needed for right air to fuel mixture. There are numerous problems that are associated with a bad MAF sensor ranging from surging, stalling, rough idle and other driveability complaints and the Electronic Engine Control system is known to be able to sense different problems with the MAF sensor and set a range of trouble codes. To verify power to the MAF sensor remove the connector of the sensor and place the positive probe of the voltmeter to the B+ terminal of the harness connector then the negative probe to the connector GND terminal, while the ignition should be on without turning the engine on the voltmeter, should read over 10 volts. When reconnecting the electrical connector, backprobe the MAF SIG and GND terminal with the voltmeter while starting the engine, expecting to see the reading to be between 1.0 and 1.7 volts at idle as the RPM increases the reading should go to between 1.7 and 3.0 volts. The customers should turn off the engine, unplug the MAF harness connector, and by using an ohmmeter, touch one probe to the MAF SIG terminal and the other probe to the GND terminal; if the circuit is open, it means that the hot-wire element is damaged. If voltage is correct, look at the wiring harness for opens or damaged part of it. If drivability issues remain and all test results are normal, the sensor should be taken to a professional workshop as voltage signal abnormalities cannot be detected with a voltmeter. For replacement, the plastic MAF sensor body and the metal air duct must be replaced simultaneously, since the two are bend together and it is not possible to replace them individually. Unplug the electrical connector of the MAF sensor, unbolt the clamp that anchors the sensor to the intake air duct, and then remove the four nuts connecting the sensor to the air cleaner housing before installing a new one with its electrical connector.

Related Nissan Quest Parts

Browse by Year

2017 Mass Air Flow Sensor 2016 Mass Air Flow Sensor 2015 Mass Air Flow Sensor 2014 Mass Air Flow Sensor 2013 Mass Air Flow Sensor 2012 Mass Air Flow Sensor 2011 Mass Air Flow Sensor 2010 Mass Air Flow Sensor 2009 Mass Air Flow Sensor 2008 Mass Air Flow Sensor 2007 Mass Air Flow Sensor 2006 Mass Air Flow Sensor 2005 Mass Air Flow Sensor 2004 Mass Air Flow Sensor 2003 Mass Air Flow Sensor 2002 Mass Air Flow Sensor 2001 Mass Air Flow Sensor 2000 Mass Air Flow Sensor 1999 Mass Air Flow Sensor 1998 Mass Air Flow Sensor 1997 Mass Air Flow Sensor 1996 Mass Air Flow Sensor 1995 Mass Air Flow Sensor 1994 Mass Air Flow Sensor 1993 Mass Air Flow Sensor