×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

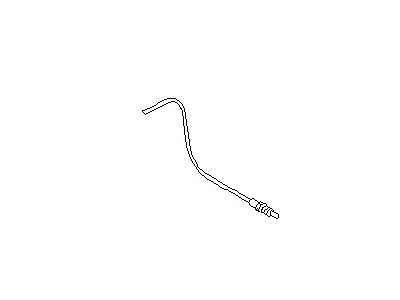

Genuine Nissan Quest Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Oxygen Sensors found

Nissan Quest Rear Heated Oxygen Sensor

Part Number: 226A0-EN21A$200.53 MSRP: $296.92You Save: $96.39 (33%)Ships in 1-3 Business Days

Nissan Quest Heated Oxygen Sensor

Part Number: 226A0-JA10C$217.41 MSRP: $321.92You Save: $104.51 (33%)Ships in 1-3 Business Days

Nissan Quest Rear Heated Oxygen Sensor

Part Number: 226A0-3NT0A$215.75 MSRP: $319.47You Save: $103.72 (33%)Ships in 1-2 Business Days

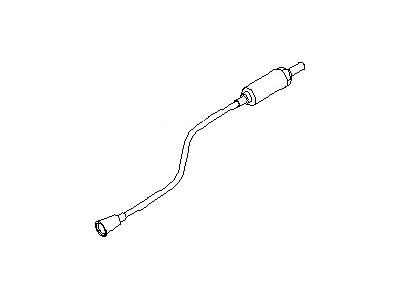

Nissan Quest Air Fuel Ratio Sensor

Part Number: 22693-1PM0A$260.56 MSRP: $385.82You Save: $125.26 (33%)Ships in 1-3 Business Days

Nissan Quest Air Fuel Ratio Sensor

Part Number: 22693-1JA0A$265.78 MSRP: $393.55You Save: $127.77 (33%)Ships in 1-3 Business Days

Nissan Quest Oxygen Sensor

Part Number: 22693-1MR0A$239.29 MSRP: $354.32You Save: $115.03 (33%)Ships in 1-2 Business Days

Nissan Quest Heated Oxygen Sensor

Part Number: 226A1-AR210$187.52 MSRP: $277.67You Save: $90.15 (33%)Ships in 1-3 Business Days

Nissan Quest Rear Heated Oxygen Sensor

Part Number: 226A0-1HC0A$221.55 MSRP: $328.05You Save: $106.50 (33%)Ships in 1-2 Business Days

Nissan Quest Heated Oxygen Sensor

Part Number: 226A0-BV81A$211.03 MSRP: $349.97You Save: $138.94 (40%)Ships in 1-3 Business Days

Nissan Quest Heated Oxygen Sensor

Part Number: 226A0-AR210$158.75 MSRP: $235.07You Save: $76.32 (33%)Ships in 1-3 Business Days

Nissan Quest Heated Oxygen Sensor

Part Number: 226A0-4AY0A$189.65 MSRP: $280.82You Save: $91.17 (33%)Ships in 1-3 Business Days

Nissan Quest Lambda Heated Sensor

Part Number: 226A0-BV80A$236.35 MSRP: $349.97You Save: $113.62 (33%)Ships in 1-3 Business DaysNissan Quest Heated Oxygen Sensor

Part Number: 226A0-7B014$110.65 MSRP: $156.28Limited AvailabilityYou Save: $45.63 (30%)

| Page 1 of 2 |Next >

1-20 of 26 Results

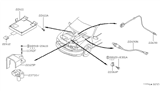

Nissan Quest Oxygen Sensor

If you need any OEM Nissan Quest Oxygen Sensor, feel free to choose them out of our huge selection of genuine Nissan Quest Oxygen Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Oxygen Sensor Parts Questions & Experts Answers

- Q: How should you inspect and test an oxygen sensor, and what are the steps for its replacement on Nissan Quest?A:If tests show that a sensor is normal and cannot be causing any driveability problem, check wiring harness and connectors between that sensor and PCM for opens or shorts. : If none of the above is present the vehicle should be taken for an assessment by an A-grade facility. The exhaust mixes with the O2S and produces voltage output which will range 0.1V, which is a lean cylinder to 0.9V, which is a rich cylinder. The upstream O2S informs the PCM concerning the state of the oxygen in the exhaust for the best setting of the air/fuel mixture thats 14.7:1 to minimize emissions, fuel consumption, and achieve top performance. The downstream O2S appears similar to the upstream sensor it does not affect air/fuel ratio, but rather is employed for evaluating the functioning of the catalyst. O2S does not generate voltage until it ascends up to around 600 degree F, this period the PCM in turns runs with open-loop depending on other sensors. The flow of electricity should be accurately connected, the air supply should be unhampered in its quantity and access to correct operating temperature, and unleaded fuel is recommended. The EEC system of the O2S can monitor different problems and set the DTCs; when a fault is present, PCM will switch to the open-loop control. In checking, attach a voltmeter to the O2S connector; the reading should be positioned at about 400 to 450 mV with the ignition on. When the engine is warmed up the upstream sensor reading should be oscillating from 100 to 900mv and downstream should be steady at sometime in the same range. Also, perform a check on the battery voltage supply to the O2S heating circuits, specifically, with the ignition on, the amount should be over 10 volts. When removing an O2S, it is recommended to warm up the engine to make it easy for removal of the part; be careful not to damage the pigtail as well as the connector; prevent the accumulation of any contaminants; and do not use any cleaning solvents. When the vehicle is raised safely and secured, remove the electrical connector, use the right tool to remove the headset and if the compound is not pre-coated, apply the anti-seize on the threads, then fit in the new sensor, tighten it and fit back the electrical connector.

Related Nissan Quest Parts

Browse by Year

2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor 2002 Oxygen Sensor 2001 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor 1998 Oxygen Sensor 1997 Oxygen Sensor 1996 Oxygen Sensor 1995 Oxygen Sensor 1994 Oxygen Sensor 1993 Oxygen Sensor