×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Rogue Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Shock Absorbers found

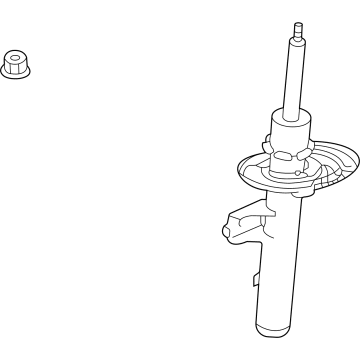

Nissan Rogue Rear Shock Absorber Kit

Part Number: E6210-JM01A$134.76 MSRP: $195.17You Save: $60.41 (31%)Ships in 1-3 Business Days

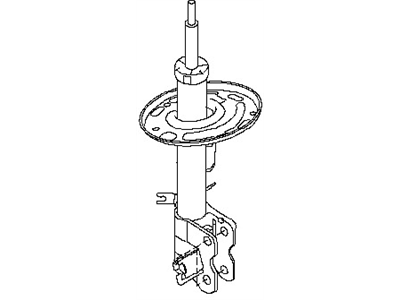

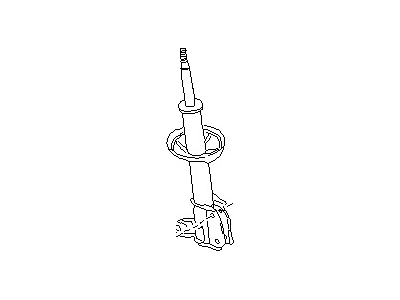

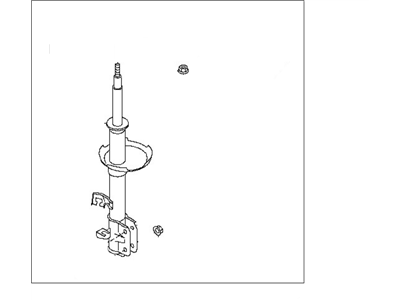

Nissan Rogue Strut Kit Front Right Hand

Part Number: E4302-4BF1C$173.45 MSRP: $256.83You Save: $83.38 (33%)Ships in 1-2 Business Days

Nissan Rogue Strut Kit Front Right Hand

Part Number: E4302-5HL0A$367.19 MSRP: $560.42You Save: $193.23 (35%)Ships in 1-3 Business Days

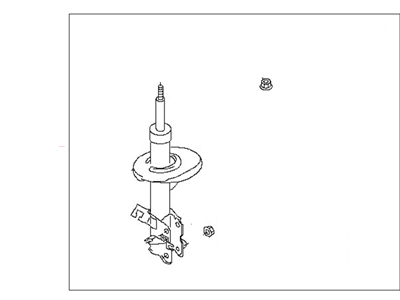

Nissan Rogue Strut Kit Front Left Hand

Part Number: E4303-5HL0A$367.19 MSRP: $560.42You Save: $193.23 (35%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Left Hand

Part Number: E4303-4BF1C$173.45 MSRP: $256.83You Save: $83.38 (33%)Ships in 1-2 Business Days

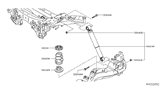

Nissan Rogue Shock Absorber Kit Rear

Part Number: E6210-4BA1C$130.60 MSRP: $189.15You Save: $58.55 (31%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Left Hand

Part Number: E4303-4BA1C$188.69 MSRP: $279.40You Save: $90.71 (33%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Left Hand

Part Number: E4303-5HA3A$367.19 MSRP: $560.42You Save: $193.23 (35%)Ships in 1-3 Business Days

Nissan Rogue Shock Absorber Kit Rear

Part Number: E6210-5HL0A$128.30 MSRP: $185.82You Save: $57.52 (31%)Ships in 1-2 Business Days

Nissan Rogue Front Suspension Strut Kit Right Hand

Part Number: E4302-JM00A$136.68 MSRP: $197.95You Save: $61.27 (31%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Right Hand

Part Number: E4302-4BA1D$188.79 MSRP: $279.55You Save: $90.76 (33%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Right Hand

Part Number: E4302-5HA3A$367.19 MSRP: $560.42You Save: $193.23 (35%)Ships in 1-3 Business Days

Nissan Rogue Strut Kit Front Left Hand

Part Number: E4303-4BA1D$188.79 MSRP: $279.55You Save: $90.76 (33%)Ships in 1-3 Business Days

Nissan Rogue Shock Absorber Kit Rear

Part Number: E6210-5HA0B$128.30 MSRP: $185.82You Save: $57.52 (31%)Ships in 1-2 Business Days

Nissan Rogue Front Suspension Strut Kit Left Hand

Part Number: E4303-JM00A$207.47 MSRP: $307.20You Save: $99.73 (33%)Ships in 1-3 Business DaysNissan Rogue STRUT Kit Ft RH

Part Number: E4302-6RA1D$219.45 MSRP: $324.93You Save: $105.48 (33%)Ships in 1-3 Business DaysNissan Rogue STRUT Kit Fr LH

Part Number: E4303-6RA1D$219.45 MSRP: $324.93You Save: $105.48 (33%)Ships in 1-3 Business DaysNissan Rogue Shock Absorber Kit Rear

Part Number: E6210-5HA1B$132.50 MSRP: $191.90You Save: $59.40 (31%)Nissan Rogue Rear Shock Absorber Kit

Part Number: E6210-4BA1D$121.68 MSRP: $177.92You Save: $56.24 (32%)Ships in 1-3 Business DaysNissan Rogue Front Suspension Strut Kit Left Hand

Part Number: E4303-1VK0A$138.63 MSRP: $205.27You Save: $66.64 (33%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Nissan Rogue Shock Absorber

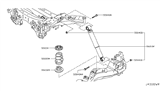

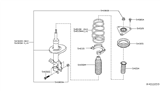

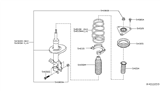

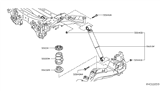

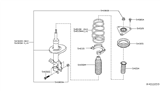

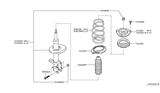

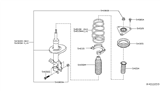

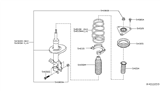

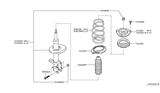

The Shock Absorber is an essential part of Nissan Rogue features which delivers it from suspension system specializing that is prominent for its integrity and high efficiency. Built to reduce the effectiveness of the shock impulses, the Shock Absorber also improves the steadiness and smoothness of the vehicle's ride. The Shock Absorber dissipates energy through heat, and thus reduces high amplitude oscillations, thus in combination with the springs controlling the vibrations. Different Nissan Rogue models have applied Shock Absorber of twin tube and mono tube which has varying feature and aspect. Twin-tube shocks are popular due to their simplicity and ease in manufacturing while the mono-tube shocks are more superior in heat management and therefore better in their performance. There is features like position sensitive damping or PSD or magnetorheological damper that make Shock Absorber more sophisticated and more capable in a variety of driving situations to improve comfort and control. This flexibility not only increases performance but boosts up the safety of Nissan Rogue and that's why Nissan Rogue stands out in the automotive industry. The Nissan Rogue which entered the automotive market in 2007 has gone through many generations of production and remains one of the top-selling compact crossovers SUV due to its excellent Shock Absorber. Consequently, the Shock Absorber continues a crucial role as one of Nissan's key components, which embody quality and innovations for driving experiences.

If you need any OEM Nissan Rogue Shock Absorber, feel free to choose them out of our huge selection of genuine Nissan Rogue Shock Absorber. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Rogue Shock Absorber Parts Questions & Experts Answers

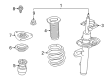

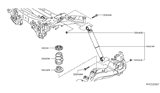

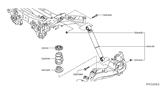

- Q: What should you consider when struts or coil springs show signs of wear on Nissan Rogue?A:If the struts or coil springs exhibit signs of wear like fluid leakage, deterioration of ability to damp, or if the physical condition is compromised through chipped or cracked then before beginning with any work, one should consult as strut/shock absorber assemblies are non-repairable if there are issues with it. Ordinary strut assemblies with springs may also be obtained on an exchange basis with a view to easing the process; it is therefore advisable to establish the cost and availability of the parts beforehand. It is dangerous to disassemble a strut, sometimes body harm can occur; utilize a high-quality spring compressor, read the user instructions thoroughly. After replacing the old coil spring with the new one within the strut assembly, put the old one in a secure place. When disassembling, it is necessary to initially unbolt the strut and spring assembly and after that fasten the strut and spring on a wooden plank with rags to avoid damaging them, though should not apply excessive force. Screw the spring compressor to the standards as recommended by the manufacturer and tighten the spring until the pressure is lifted out from the upper spring seat that can be ascertained by moving the spring. Subsequently, use an Allen wrench to unlock the piston rod nut and then unscrew the upper supporting bracket of suspension and examine the bearing to see if it can run smoothly, and if not, the entire bearing should be replaced. Loosen the suspension support bolt and look at the rubber part to see if there is any signs of separation and replace them if there has been. Release the lower end of the spring and pull the spring seat along with the upper insulator off the piston rod; it is important to inspect the rubber spring seat and if it is damaged then replace it. Pick the compressed spring from the assembly gently and put it aside, being cautious and avoiding contact with the ends of the spring with body parts. Slide the dust boot off the piston rod and determine if the lower insulator is worn out and needs to be replaced. For reassembly, if fitting new lower insulator, align it in the right position and further insert the damper rod and place the dust boot in its maximum length. Put the coil spring to the lower insulator with the end seated in the recessed portion of the insulator. Applying the mark or the arrow, you have to fix the upper insulator and spring seat in a way that their arrows are out of phase. Lastly, screw on and fix the dust seal and suspension support on the piston rod the torque the nut as per the recommended torque, replace the strut or shock absorber along with the coil spring.

Related Nissan Rogue Parts

Browse by Year

2025 Shock Absorber 2024 Shock Absorber 2023 Shock Absorber 2022 Shock Absorber 2021 Shock Absorber 2020 Shock Absorber 2019 Shock Absorber 2018 Shock Absorber 2017 Shock Absorber 2016 Shock Absorber 2015 Shock Absorber 2014 Shock Absorber 2013 Shock Absorber 2012 Shock Absorber 2011 Shock Absorber 2010 Shock Absorber 2009 Shock Absorber 2008 Shock Absorber