×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

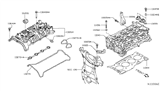

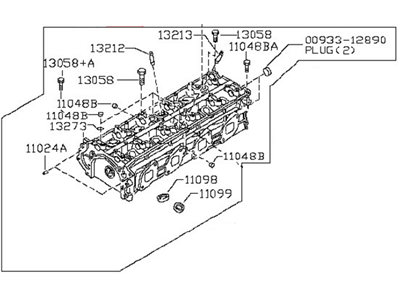

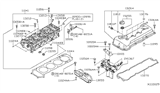

Genuine Nissan Versa Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Cylinder Heads found

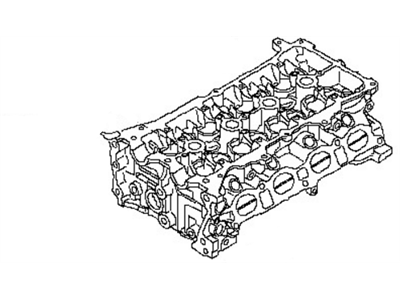

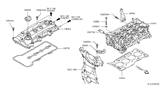

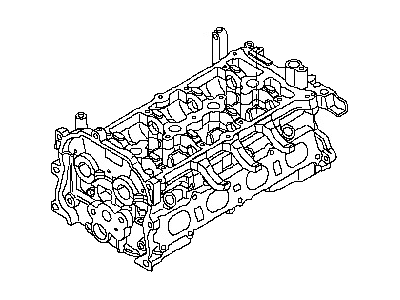

Nissan Versa Cylinder Head Assembly

Part Number: 11040-1KT0A$1295.59 MSRP: $1568.51You Save: $272.92 (18%)Ships in 1-3 Business DaysNissan Versa Cylinder Head

Part Number: 11040-5H70A$893.07 MSRP: $1261.40You Save: $368.33 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head Assembly

Part Number: 11040-5RL0A$1423.21 MSRP: $1723.01You Save: $299.80 (18%)Ships in 1-3 Business DaysNissan Versa Cylinder Head Assembly

Part Number: 11040-EL00A$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head

Part Number: 11040-ZJ80B$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head

Part Number: 11040-ZJ80A$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head

Part Number: 11040-EE000$893.07 MSRP: $1261.40You Save: $368.33 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head

Part Number: 11040-ZJ80C$776.37 MSRP: $1096.57You Save: $320.20 (30%)Ships in 1-3 Business DaysNissan Versa Cylinder Head Assembly

Part Number: 11040-3AB5A$1295.59 MSRP: $1568.51You Save: $272.92 (18%)

Nissan Versa Cylinder Head

If you need any OEM Nissan Versa Cylinder Head, feel free to choose them out of our huge selection of genuine Nissan Versa Cylinder Head. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa Cylinder Head Parts Questions & Experts Answers

- Q: How do you remove and install a cylinder head on Nissan Versa?A:But before one can begin the process of removing the cylinder head, it is important for the fuel system's pressure to be released and the engine to be turned to TDC compression for cylinder No 1 as well as disconnecting the cable of the negative terminal of the battery. Siphon off the coolant, undo the timing chain as well as the cam shafts, Exhaust Manifold, and the Intake Manifold. All tubing, wiring, cables, hoses, or fittings that might still be connected to the cylinder head must be removed or labeled. The cylinder head bolts can be removed using a breaker bar along with the corresponding size hex bit by loosening the same gradually in such a way that these bolts could be unscrewed by hand and the sequence for loosening should be in the reverse of that in which it was tightened so that it can't war or crack. Raise the cylinder head off the engine block using a hydraulic lift and pry it off if it is tacky, then pull out all the external fittings for thorough degreasing and check. For installation, the mating surfaces of the cylinder head and block should be free from any forms of contaminant, by scraping off the carbon and old gasket materials with gasket scraper before washing off with lacquer thinner or acetone. Inspect the block and cylinder head mating areas and if there are slight ones, they are filed with a fine file or if there heavy ones then it has to be machined. Whenever the cylinder head bolts are removed, chase the threads in the corresponding bolt holes with a tap and then blow the holes with compressed air. Once cleanliness of the gasket surface of cylinder head is confirmed, look for warpage of the machined surface and the condition of the cylinder head gasket, intake as well as exhaust manifold gasket surfaces. Replace any components that you remove from the cylinder head, align the new cylinder head gasket with the dowel pins in the block, and then very slowly lower the cylinder head onto the block over the gasket. Grease a new set of cylinder head bolts even though clean engine oil to the threads and hardened washers' chamfered side must face the bolt heads. Bolt in the new cylinder head bolts and tighten them to the correct torque following the sequence. Then install the lifters and camshafts, followed up with the timing chain and then adjust the valve clearances. The remaining of the installation is the converse order of the removal process. Replace the old coolant with new one, change the oil filter, check and add the oil levels, reconnect the battery and do the required re-learn process.

Related Nissan Versa Parts

Browse by Year

2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head