×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Pathfinder Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

34 Drive Belts found

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-EA200$58.29 MSRP: $84.42You Save: $26.13 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Fan & Alternator Belt

Part Number: 02117-92523$34.13 MSRP: $49.43You Save: $15.30 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Belt-Fan

Part Number: 11720-6TA0A$61.69 MSRP: $89.35You Save: $27.66 (31%)Ships in 1-2 Business Days

Nissan Pathfinder Alternator Belt

Part Number: 11720-7S00A$75.43 MSRP: $109.25You Save: $33.82 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-4P102$69.02 MSRP: $99.97You Save: $30.95 (31%)Ships in 1-2 Business Days

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-3WS0B$61.69 MSRP: $89.35You Save: $27.66 (31%)Ships in 1-2 Business Days

Nissan Pathfinder Compressor Belt

Part Number: 11920-AG900$38.59 MSRP: $55.90You Save: $17.31 (31%)Ships in 1-2 Business Days

Nissan Pathfinder Power Steering Oil Pump Belt

Part Number: 02117-90523$30.40 MSRP: $36.00You Save: $5.60 (16%)Ships in 1-3 Business Days

Nissan Pathfinder Alternator Belt

Part Number: 11720-3JA0A$61.69 MSRP: $89.35You Save: $27.66 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Power Steering Oil Pump Belt

Part Number: 02117-88023$23.82 MSRP: $34.50You Save: $10.68 (31%)Ships in 1 Business Day

Nissan Pathfinder Compressor Belt

Part Number: 11920-0W002$29.66 MSRP: $42.95You Save: $13.29 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-0W002$25.95 MSRP: $37.58You Save: $11.63 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Alternator Belt

Part Number: 11920-3KY0A$58.60 MSRP: $84.88You Save: $26.28 (31%)Ships in 1-3 Business Days

Nissan Pathfinder Serpentine Belt

Part Number: 11920-0W000$29.66 MSRP: $42.95You Save: $13.29 (31%)Ships in 1 Business Day

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-4P101$69.02 MSRP: $99.97You Save: $30.95 (31%)Ships in 1 Business Day

Nissan Pathfinder Compressor Belt

Part Number: 11920-V5001$42.94 MSRP: $50.58You Save: $7.64 (16%)Ships in 1-3 Business Days

Nissan Pathfinder Alternator Belt

Part Number: 11720-0W000$25.95 MSRP: $37.58You Save: $11.63 (31%)Ships in 1 Business Day

Nissan Pathfinder Fan & Alternator Belt

Part Number: 11720-V5001$34.13 MSRP: $49.43You Save: $15.30 (31%)Nissan Pathfinder Serpentine Belt

Part Number: 11920-0W001$29.66 MSRP: $42.95You Save: $13.29 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 34 Results

Nissan Pathfinder Drive Belt

If you need any OEM Nissan Pathfinder Drive Belt, feel free to choose them out of our huge selection of genuine Nissan Pathfinder Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Pathfinder Drive Belt Parts Questions & Experts Answers

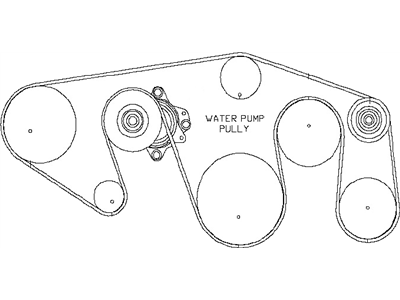

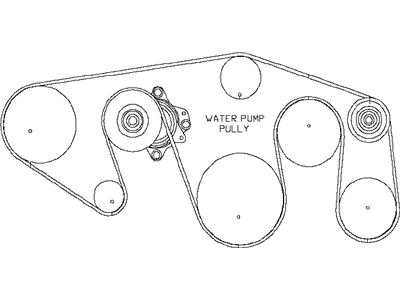

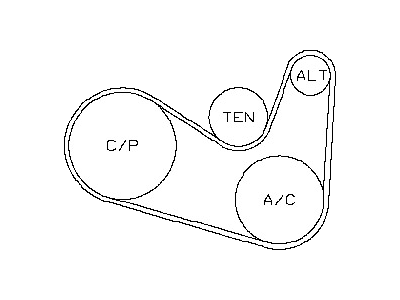

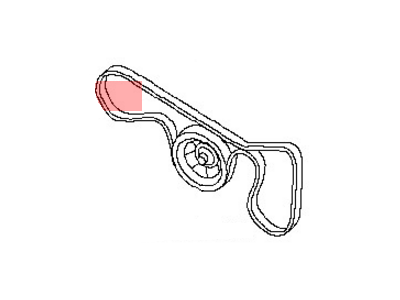

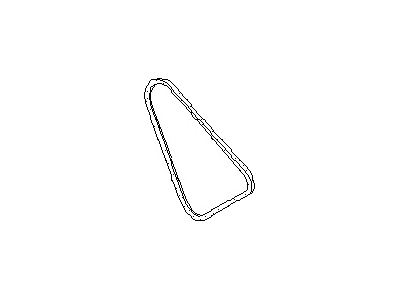

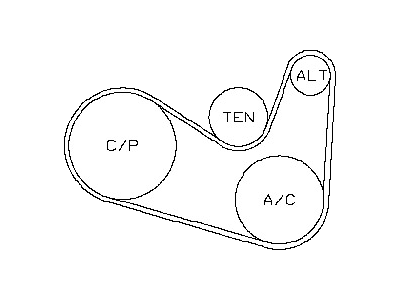

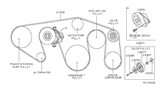

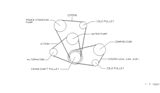

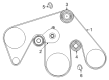

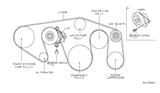

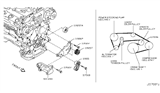

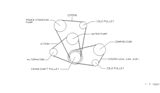

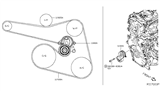

- Q: What is the role of drivebelts in the engine's operation and its components on Nissan Pathfinder?A:Drivebelts, located at the front of the engine, play a crucial role in the engine's operation and its components. They are prone to wear due to their function and material make up, and should be inspected periodically. Most models have three belts, while some only have two. To inspect, with the engine off, open the hood and use your fingers to move along the belt, checking for cracks, separation of the belt plies, fraying, and glazing, which gives the belt a shiny appearance. Both sides of the belt should be inspected, which means you will have to twist the belt to check the underside. The ribs on the underside of multi-ribbed belts should all be the same depth, with none of the surface uneven. Belt tension can be checked manually, by pushing on the belt at a distance halfway between two pulleys. If the distance from pulley center-to-pulley center is between 7 and 11 inches, the belt should deflect 1/4-inch. If the belt travels between pulleys spaced 12 to 16 inches apart, the belt should deflect 1/4 to 1/2-inch. Belts that are routed over an idler pulley are adjusted by loosening the nut in the center of the idler pulley and turning the adjusting bolt. Belts that do not have an idler pulley are adjusted by moving the driven component in its bracket. To replace the belts, loosen the idler or component until the belt can be removed from the various pulleys. On multiple-belt applications, outer belts will have to be removed to access inner belts, but all belts should be replaced at the same time. Route the new belt over the various pulleys, then adjust the tension.

Related Nissan Pathfinder Parts

Browse by Year

2025 Drive Belt 2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt 1990 Drive Belt 1989 Drive Belt 1988 Drive Belt 1987 Drive Belt