×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 240SX PCV Valve

Position Crank Ventilation Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 PCV Valves found

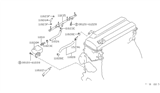

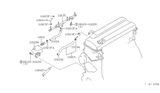

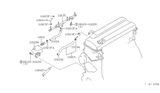

Nissan 240SX Positive Crankcase Ventilation Valve

Part Number: 11810-86G01$10.14 MSRP: $13.98You Save: $3.84 (28%)Ships in 1-3 Business Days

Nissan 240SX Positive Crankcase Ventilation Control Valve Assembly

Part Number: 11810-86G00$10.14 MSRP: $13.98You Save: $3.84 (28%)Ships in 1-2 Business Days

Nissan 240SX PCV Valve

If you need any OEM Nissan 240SX PCV Valve, feel free to choose them out of our huge selection of genuine Nissan 240SX PCV Valve. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX PCV Valve Parts Questions & Experts Answers

- Q: How do you address the situation if the PCV valve fails to produce a hissing noise and strong vacuum when the ventilation hose is removed while the engine is running at idle on Nissan 240sx?A:The crankcase emission control equipment consists of a positive crankcase ventilation valve (PCV), a closed or open oil filler cap and hoses which is meant to contain the gases that are formed in the combustion chamber during engine operation. These gases, if not removed from the crankcase, can get mixed with and contaminate engine oil leading to sludge formation are recirculated back into the engine combustion chamber where they burn up without escaping into the air polluting it. The process of recycling involves clean filtered air being drawn into the crankcase, picking up the combustion gases, and carrying them through the PCV valve and intake manifold to be used in the combustion chamber. This is a very important vacuum controlled valve in this system because it controls how much of these gases are returned to the combustion chamber. When blocked, there will be gas leaks through weak oil seals or gaskets in an engine, thus promoting sludge formation and causing oil leakage. This information along with troubleshooting instructions apply to any engine that has PCV system. To check for any leaks on hoses or connections, examine them for signs of vacuum leakages and replace or tighten as required. With all engines running at idle, disconnect the vent hose from PCV valve. If functioning correctly, there will be a hissing sound as well as strong suction from your mouth when you remove vent hose from PCV valve with your car at idle speed. In order to check for proper operation of this valve you should remove it and then blow through both ends . Air should pass freely through from crank case side but hardly move from intake manifold side . Should this occur , replace such a valve immediately . To remove PCV valve loosen clamp on hose and take off from manifold-crankcase hose as well as intake manifold . Just do installation like removal except disconnecting all hoses then use compressed air to clean them replacing any hose that cannot be blown out by air.