×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Juke Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

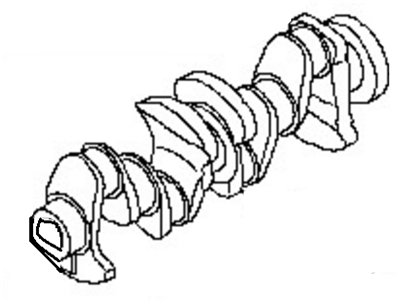

Nissan Juke Crankshaft Assembly

Part Number: 12201-1KC0A$1170.69 MSRP: $1653.52You Save: $482.83 (30%)Ships in 1-3 Business Days

Nissan Juke Crankshaft

If you need any OEM Nissan Juke Crankshaft, feel free to choose them out of our huge selection of genuine Nissan Juke Crankshaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Juke Crankshaft Parts Questions & Experts Answers

- Q: How do you check the crankshaft endfloat and what steps should be taken if wear is detected on Nissan Juke?A:To verify crankshaft endfloat, place the crankshaft in the cylinder block or crankcase but should be able to move back and forth. Ordinarily, a dial gauge touching the end of the crankshaft will be helpful, push it fully in one direction and zero the dial gauge then push the dial gauge fully in the opposite direction to measure the end float as this will determine if new thrust washers are required. Feelers can be used if a dial gauge is not available and it can measure the clearance between the No 4 crankpin web and No 3 main bearing thrustwasher, having pushed the crankshaft towards the flywheel end. Scrape clean with paraffin or choose an appropriate solvent while doing away with the crankshaft's use of compressed air and making certain that the oil holes are clear. Check the main and big-end bearing journals for wears, scoring, pitting and crack. Bearing wear on the big-end will result in metallic knocking and loss of oil pressure while in the main bearing, it results in severe vibration and rumble increasing with the increase in speeds and oil pressure loss. One should also examine the bearing journal for roughness, as any kind of roughness would mean that the journal needs to be reground or replaced. Check for wear on the flat contact surfaces of the oil seal, Deep scraper may need the service of a specialist to fix or warrant a replacement of the crankshaft. Crankshaft measurement should be accurate and this is a task that can only be done by the automotive engineering workshop, hence the appropriate journal bearings should be sourced from the same workshop in case of regrinding. After regrinding, examine case for burrs around the oil holes: if any, they should be scraped off and the entire area cleaned. This may be true only on desks stocks; if the crankshaft is worn out beyond the limit, and undersize bearings are not available, the crankshaft will have to be replaced; check with a Nissan dealer or an engine genius for the parts sizes.