×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Juke Turbocharger

Turbo- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Turbochargers found

Nissan Juke Turbo Charger

Part Number: 14411-1KC2C$1484.22 MSRP: $1791.79You Save: $307.57 (18%)Ships in 1-2 Business Days

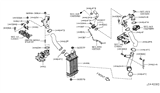

Nissan Juke Turbocharger

Part Number: 14411-1KC2B$1484.22 MSRP: $1791.79You Save: $307.57 (18%)Ships in 1-3 Business DaysNissan Juke Turbo Charger

Part Number: 14411-BV86A$1761.15 MSRP: $2127.06You Save: $365.91 (18%)Ships in 1-3 Business DaysNissan Juke Turbo Charger

Part Number: 14411-BV84B$1796.33 MSRP: $2169.64You Save: $373.31 (18%)Ships in 1-3 Business DaysNissan Juke Turbo Charger

Part Number: 14411-1KC1E$1796.33 MSRP: $2169.64You Save: $373.31 (18%)Ships in 1-3 Business DaysNissan Juke Turbo Charger

Part Number: 14411-1KC1D$1796.33 MSRP: $2169.64You Save: $373.31 (18%)Ships in 1-3 Business DaysNissan Juke Turbocharger

Part Number: 14411-1KC1B$1796.33 MSRP: $2169.64You Save: $373.31 (18%)Ships in 1-3 Business Days

Nissan Juke Turbocharger

If you need any OEM Nissan Juke Turbocharger, feel free to choose them out of our huge selection of genuine Nissan Juke Turbocharger. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

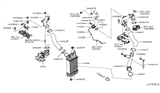

Nissan Juke Turbocharger Parts Questions & Experts Answers

- Q: How does a turbocharger enhance engine efficiency on diesel Nissan Juke?A:A turbocharger improves the performance of the engine by compressing the air in the inlet manifold, above atmospheric pressure thus pumping it into the cylinders in addition to injection of fuel in relation to the compressed air. Energy is drawn from the exhaust gas to turn a Turbine wheel located in a housing separate from the compressor which is also wheel, which through another shaft provides the needed compression to the inducted air before the mixture reaches the inlet manifold. The compressed air, subsequently, flows through intercooler, an air-to-air cooler which is located behind the front bumper with the intended aim of cooling the air to compactness and with the view of improving on efficiency of the engine. While a further pressure build up in the inlet manifold is controlled by a wastegate that opens and bypasses exhaust gas away from the turbine wheel depending on a pressure-sensing actuator and a boost pressure sensor is used to sense the turbocharging pressure. Another is the turbo shaft is lubricated by oil from the main oil gallery and floats on oil, with provision of drain pipe going to the sump. There are some specificities that must be followed because the turbo is exposed to high speeds and temperatures; do not use full throttle right after starting the car, let the car return to idle after using the gas, and let it idle for some time after using full throttle. It is recommended to change the oil and oil filter with high quality oil frequently in order to avoid building carbon on the turbo shaft and its failure.